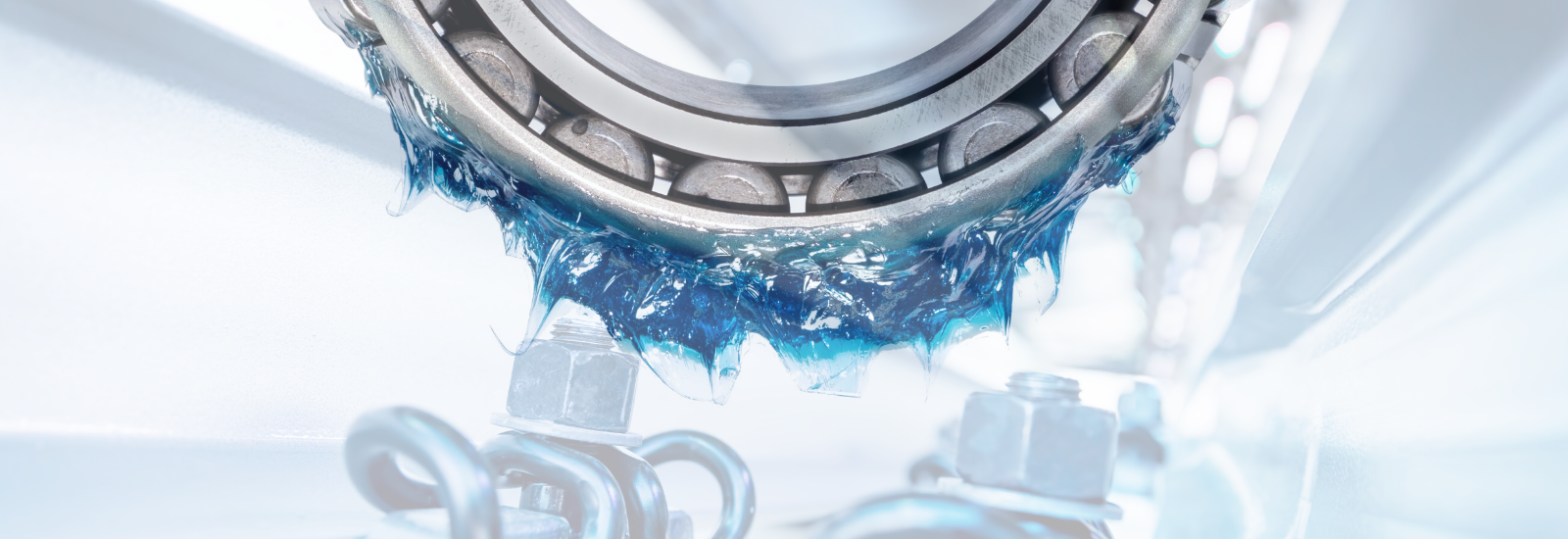

Synthetic lubricating greases are widely utilised due to their inherent ability to cling to the friction point and ensure an effective hydrodynamic film under centrifugal conditions and potential detachment from the friction zones. The correct balance of the components of a lubricating grease ensures the right balance between adhesiveness and the coefficient of low static and dynamic friction. Lubricating greases are essentially composed of four elements:

The choice and correct combination of its basic components enables the lubricating grease to suit the application context in which it operates, namely the tribosystem – as the set of conditions affecting the immediate surroundings of a friction process.

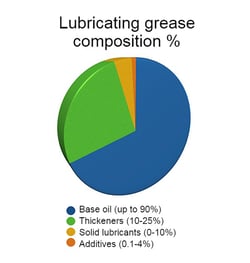

The element that affects the performance of a grease more than any other is the base oil, which can be up to 90% by weight in the softest grades of grease (NLGI 000).

It can be distinguished by:

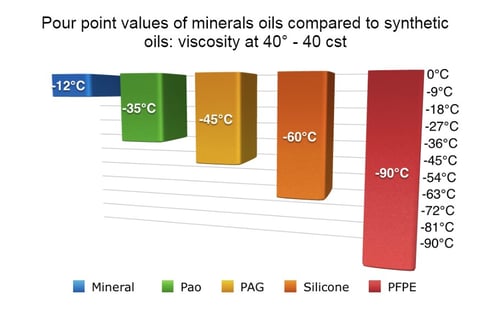

In terms of performance, in a comparison between mineral and synthetic oils, the latter are able to withstand much harsher conditions:

A modern design of mechanical components in the automotive, appliance, military and aerospace sectors need synthetic oils, which are divided into five main macro-families within which specific differences can be isolated:

Synthetic lubricating greases thus inherit the strengths of the oils from which they are formulated and are the obvious choice in conditions of:

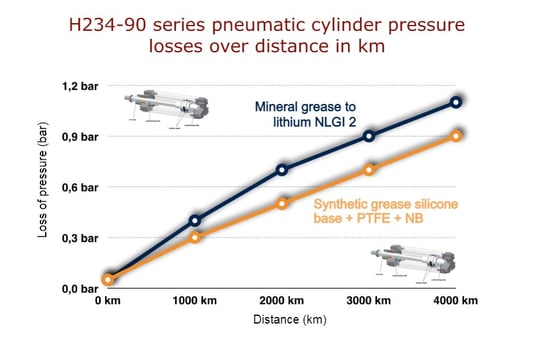

Synthetic lubricating greases are the preferred choice in all application contexts involving long-life lubrication – the assembly of the mechanical component coincides with the only possible lubrication foreseen due to the objective impossibility of performing intermediate maintenance operations to restore the lubrication film.

The mechanical devices that comprise and equip a vehicle are a classic example of the need to find a lubricant solution that is effective and long-lasting enough to complete the drive and reset cycles that occur throughout the life of the vehicle. Other examples include:

Amongst the most effective and tested product families for the lubrication of original equipment components are:

HEAD OFFICE:

Macon Research Srl

Via Santa Lucia, 8/D

36056 Tezze sul Brenta (VI)

Tel.+39 0424.57.39.66

Fax.+39 0424.57.39.66

Mail: info@maconresearch.com

ADMINISTRATIVE OFFICE:

Macon Research Srl

Via L. Tolstoj, 43/O

20098 San Giuliano Milanese (MI)

Tel.+39 02.98.24.41.61

Fax.+39 02.98.24.4161

Mail : info@maconresearch.com

The data contained in this catalogue are based on our general experience and knowledge at the time of publication and are intended to provide the reader with technical information about any possible uses. This information does not, however, constitute an assurance as regards product characteristics in relation to specific cases. We recommend that you request an interview with our consultants. We would be happy to provide you with samples.