Effective heat dissipation can only occur between materials with a high conductivity coefficient. A poorly-designed heat-transfer chain can cause energy and efficiency losses or even an interruption to the dissipative effect with a corresponding loss of functionality of the mechanical device.

The most frequent cases in which it is necessary to rapidly transfer heat from one element to another can be traced back to:

The methodologies available on the market are varied, effective and require a precise analysis of the thermal and environmental operating conditions for:

In some cases, however, the use of a "rigid" solution may not be adequate for the application context, due for example to the lack of flatness and the consequent interposition of insulating air pockets between the conductive foils, the presence of which would compromise the dissipative effect since air is a mixture of gases with a low conductivity coefficient when compared to metals or other conductive materials.

In such cases, the use of a thermal-conductive paste can help.

A thermal conductive paste is a plastic compound with high thermal conductivity that accommodates the geometric imperfections of the coupling. A good heat-conducting paste must be carefully selected, taking into consideration:

The selection of the conductive filler and its heat transfer coefficient both condition the dissipation efficiency, whilst the base oil, additives and thixotropic agents determine other key properties, such as:

A thermal paste is classified on the basis of its specific thermal conductivity, the value of which is primarily conditioned by the type of filler and its concentration.

The production of a thermal paste requires a process that must be constantly controlled. An often-overlooked problem is the potential incorporation of air into the finished product, the presence of which would lead to a drastic reduction in the heat exchange coefficient and consequent heat dissipation.

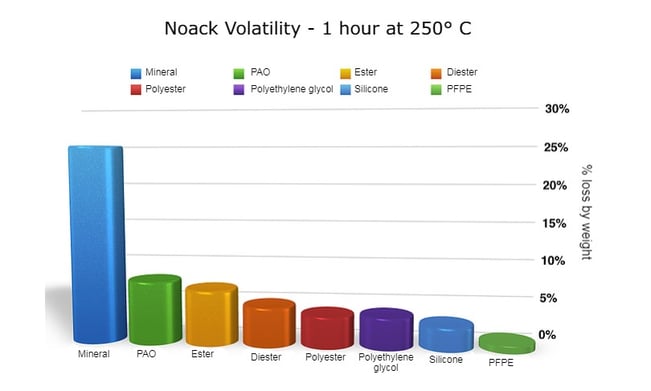

Another fundamental aspect concerns the choice of base oil, which significantly influences stability at different operating temperatures. In particular at:

Adhesion to the friction zones and the potential loss of material by gravity from the heat transfer zones represent one possible threat to the proper functioning of the device. For this reason, it is possible to perform a specific adhesion test by checking the rheological and visco-dynamic properties of the product in use in the thermal operating range provided by the application context.

Scopri di più

Scopri di più

Grasso lubrificante a base di polidimetilsilossano per cilindri a basso attrite risparmio energetico

Scopri di più

Grasso lubrificante a base sintetica per cilindri pneumatici con anelli di tenuta in EPDM

Scopri di più

Grasso lubrificante base PAO omologato per contatto accidentale con alimento

Maconsynth GT1/B

Grasso lubrificante a base di idrocarburo sintetico per cilindri pneumatici senza stelo

Pneugrease HTS

Grasso lubrificante a base di polidimetilsilossano per cilindri a basso attrite risparmio energetico

Maconsynth Retrac 400

Grasso lubrificante a base sintetica per cilindri pneumatici con anelli di tenuta in EPDM

Ultragrease ATOX 2

Grasso lubrificante base PAO omologato per contatto accidentale con alimento

HEAD OFFICE:

Macon Research Srl

Via Santa Lucia, 8/D

36056 Tezze sul Brenta (VI)

Tel.+39 0424.57.39.66

Fax.+39 0424.57.39.66

Mail: info@maconresearch.com

ADMINISTRATIVE OFFICE:

Macon Research Srl

Via L. Tolstoj, 43/O

20098 San Giuliano Milanese (MI)

Tel.+39 02.98.24.41.61

Fax.+39 02.98.24.4161

Mail : info@maconresearch.com

The data contained in this catalogue are based on our general experience and knowledge at the time of publication and are intended to provide the reader with technical information about any possible uses. This information does not, however, constitute an assurance as regards product characteristics in relation to specific cases. We recommend that you request an interview with our consultants. We would be happy to provide you with samples.