Lubricating oils and thermo-viscosity

Amongst the fundamental characteristics of a lubricating oil, viscosity represents the most important property, together with the chemical composition.

A lubricating oil, while promoting smoothness and protection from mechanical wear between two surfaces in reciprocal movement, introduces a friction whose value is closely related to its viscosity at a given operating temperature.

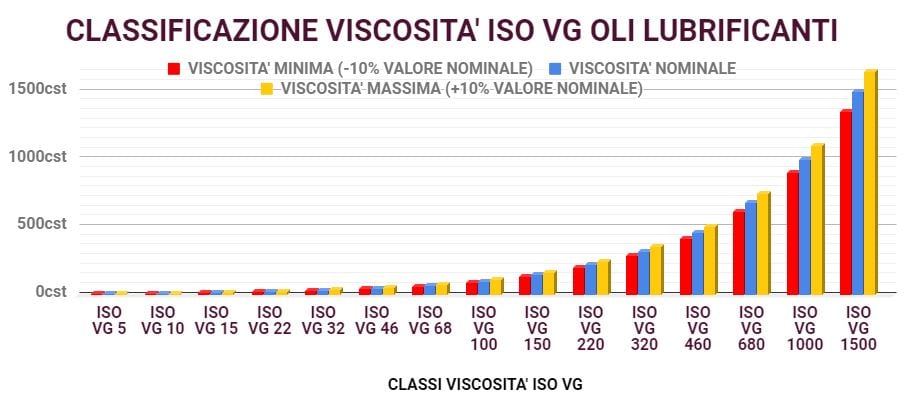

There are several international standards used for the classification of the viscosity of a lubricating oil. The most commonly used in industrial lubrication is the ISO VG classification, where at around a nominal value of reference measured at 40° C, a tolerance of +/-10% is stable. The range of acceptance is required by both lubricating oil manufacturers and users alike.

The graph below identifies 15 viscosity classes, from ISO VG 5 up to 1500. Each class is distinguished by a gradient of +/-50% of its nominal value.

ISO VG VISCOSITY CLASSIFICATION LUBRICATING OILS

MINIMUM VISCOSITY (-10% NOMINAL VALUE) NOMINAL VISCOSITY

MAXIMUM VISCOSITY (+ 10% NOMINAL VALUE)

ISO VG VISCOSITY CLASSES

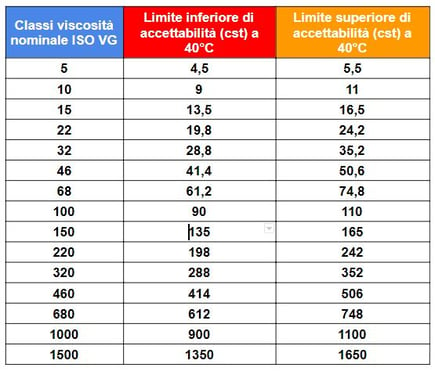

ISO VG nominal viscosity classes

Lower limit of acceptability (cst) at 40° C

Upper limit of acceptability (cst) at 40 ° C

What factors affect viscosity?

The unit of measurement that defines the viscosity value of an oil is the cst (centistokes) or cps (centipoises) and measures the value of its internal friction.

The viscosity of a lubricating oil, like any organic fluid present in nature, varies in relation to the temperature and it is for this reason that the choice of the most suitable oil for the lubrication of a mechanical device must start from the identification of the thermal regime or working temperature, being the maximum and minimum operating temperature.

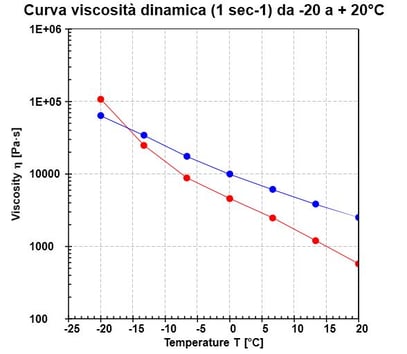

The viscosity of an oil varies, as shown in the image, inversely proportional to the temperature. Its value decreases with the rise in the thermal load.

Dynamic viscosity curve (1 sec-1) from -20° to +20° C

The variation in an oil's viscosity introduces negative phenomena into the friction process in terms of the wear protection of the contact points. Its reduction then results in a thinning of the lubrication film and a consequent exposure of the surfaces to the risk of premature wear. Its increase at low temperatures, rather, produce a rise in viscous friction up to the blockage of the kinematic mechanism at the freezing point of the lubricating oil.

What is meant by thermo-viscosity stability?

A lubricating oil is stable from a visco-thermal point of view when it exhibits minimal variations in viscosity as the temperature varies.

Is it possible to limit the variation of viscosity with temperature?

All lubricating oils have a characteristic viscosity curve, the trend of which can be summarised with a number to help the formulator and the mechanical designer in choosing. To translate in numerical terms, the entity of the variation of the viscosity of an oil with the variation of the temperature of use:

- The viscosity index

- The viscosity temperature coefficient

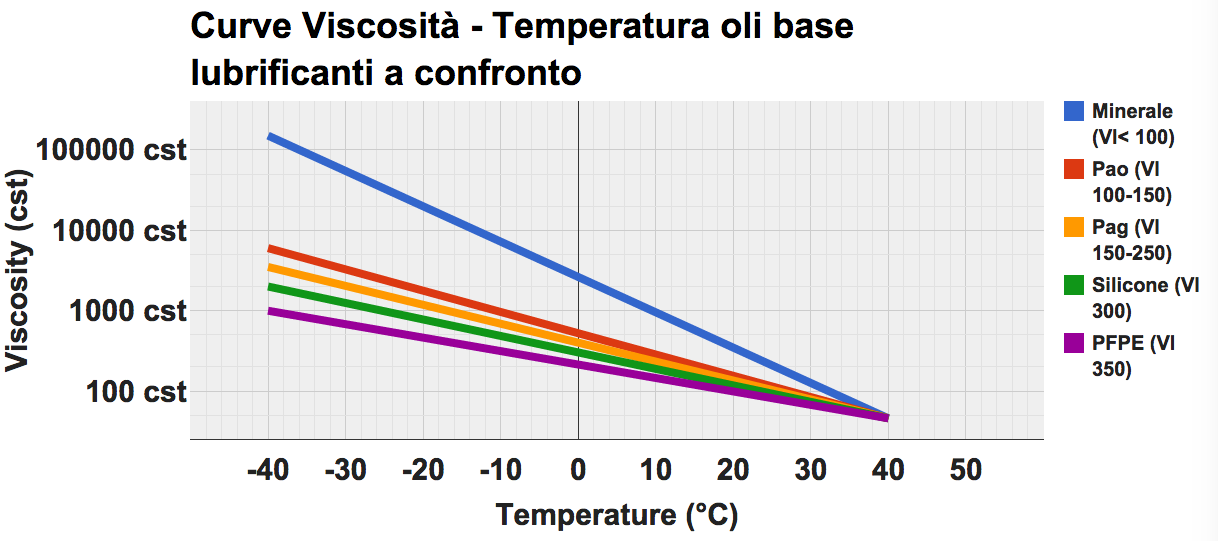

The viscosity index is a dimensionless number (with no specific unit of measurement). For mineral lubricating oils (cheaper), the viscosity index value is around 90-100 up to values of 300-350 for the more stable synthetic lubricating solutions. 5 lubricating oils of different chemical composition characterised by the same viscosity value measured at 40° C are shown below. It is evident that at -40° C, the orders of magnitude depending on the chemical composition are different for:

- Mineral oil

- Polialfaolefinco oil

- Polyalkene glycol oil

- Silicone oil

- Perfluoropolyether oil

Viscosity curves - Lubricant base oil temperatures compared

Mineral

How to check and guarantee a good thermo-viscosity?

To limit the variation of viscosity with temperature, it is possible to operate in 3 ways:

- Additives - usually starting from lubricating oils of mineral composition, the choice of which falls for economic reasons, it is possible to add small percentages of additives whose action is effective in moving the freezing point to lower temperatures

- Chemical composition - as shown in the image, the choice of a synthetic lubricating solution (PAO/PAG/SIL/PFPE) can favour a more extended operating thermal range both in terms of viscothermic stability and in terms of thermo-oxidative stability, which is appreciable at elevated operating temperatures (read our article for further information: Mineral oil vs Synthetic oil)

- Mixing/cutting - if lubricating fluids of a different chemical nature are compatible with each other (for example, minerals and PAO) then it is possible to make mixtures to limit the variation of the viscosity of the mineral oil by exploiting the best viscosity temperature behaviour of the synthetic polyalphaolefinic oil (PAO)

Solutions 2 and 3 introduce an increase in the cost of raw materials, the choice of which can only be justified by the application context of the component to be lubricated.