What is certain is that over the decades, plastics have come to conquer all industries. Improved production technologies and the development of new materials have made it possible to replace fields of application that were once the exclusive domain of metallic materials.

Having ascertained the effectiveness of plastics over metals, however, there remains great doubt as to their compatibility with the lubricants applied to ensure optimal friction performance and durability.

Are you sure that the lubricating grease you are currently using for plastics won't alter their mechanical properties?

Very often the processes behind a structural weakening of plastics caused by chemical interactions with lubricating fluids are slow and not easy to predict.

The possibility of premature damage to plastic parts is not always easy to analyse given that a range of variables can synergistically combine and produce very significant alterations in the mechanical properties of plastics.

One important distinction between plastic polymers is made between:

Plastics consist of a combination of the two structures, where the lower the percentage of the crystalline component, the higher the risk of chemical attack by lubricants in contact

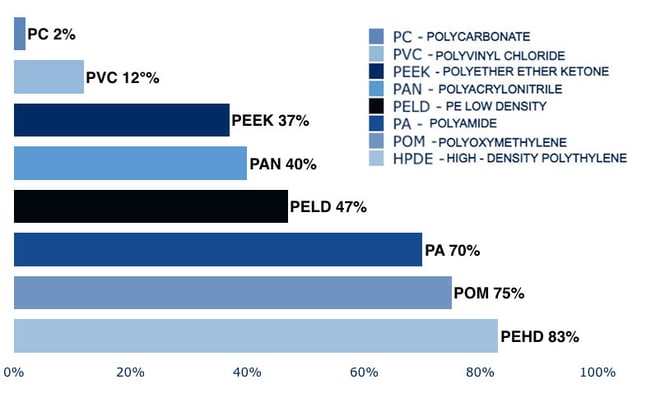

Here are some examples of structure composition based on the average level of crystallinity:

What are the effects of using the wrong plastic lubricant? A concentration of the destructive effects and/or depletion of mechanical characteristics due to weathering combined with the effect of lubrication is called Environmental Stress Cracking (ESC).

The most common effects that can occur are:

Which plastics are most commonly used for the production of mechanical components?

The numerous chemical varieties available on the market today make organic classification and subdivision difficult.

Amongst the most common are:

Scopri di più

Scopri di più

Grasso lubrificante a base di polidimetilsilossano per cilindri a basso attrite risparmio energetico

Scopri di più

Grasso lubrificante a base sintetica per cilindri pneumatici con anelli di tenuta in EPDM

Scopri di più

Grasso lubrificante base PAO omologato per contatto accidentale con alimento

Maconsynth GT1/B

Grasso lubrificante a base di idrocarburo sintetico per cilindri pneumatici senza stelo

Pneugrease HTS

Grasso lubrificante a base di polidimetilsilossano per cilindri a basso attrite risparmio energetico

Maconsynth Retrac 400

Grasso lubrificante a base sintetica per cilindri pneumatici con anelli di tenuta in EPDM

Ultragrease ATOX 2

Grasso lubrificante base PAO omologato per contatto accidentale con alimento

HEAD OFFICE:

Macon Research Srl

Via Santa Lucia, 8/D

36056 Tezze sul Brenta (VI)

Tel.+39 0424.57.39.66

Fax.+39 0424.57.39.66

Mail: info@maconresearch.com

ADMINISTRATIVE OFFICE:

Macon Research Srl

Via L. Tolstoj, 43/O

20098 San Giuliano Milanese (MI)

Tel.+39 02.98.24.41.61

Fax.+39 02.98.24.4161

Mail : info@maconresearch.com

The data contained in this catalogue are based on our general experience and knowledge at the time of publication and are intended to provide the reader with technical information about any possible uses. This information does not, however, constitute an assurance as regards product characteristics in relation to specific cases. We recommend that you request an interview with our consultants. We would be happy to provide you with samples.