Metalworking industries producing semi-finished metal products such as pumps, valves, flanges, heat exchangers and mechanical equipment are faced with the immense problem of the costs associated with inadequate metal component protection prior to the final application of a permanent covering (coating or paint).

The production process often consists of a sequence of steps and processes that inevitably expose surfaces to atmospheric corrosion, the result of which is the transformation of the base metal into a series of ferrous chemical compounds, ergo rust.

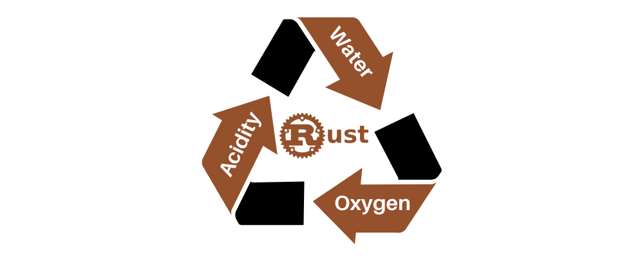

Environments favourable to deep atmospheric corrosion are essentially linked to three conditions:

The coexistence of these conditions accelerates and promotes the transformation of the base metal into a series of reaction by-products – the iron oxides – which contribute to eroding the structure by weakening the mechanical properties. If conditions remain favourable, the action of consuming material proceeds, without pause, regenerating in a cyclic manner where only the control of one of the three variables can favour the interruption or slowing down of the process.

The use of additives in baths for mechanical turning or milling operations can help slow down such phenomena, together with protective oils and corrosion inhibitors, as the most versatile solutions in the industrial sector to reduce the risks of exposure to oxidation phenomena. Their formulation includes the following elements:

Before choosing the most suitable solution, it is necessary to understand the most critical steps in the production process and the type of materials involved. Lubricating and protective solutions are classified and chosen on the basis of certain important parameters, namely:

In the metalworking industry, an effective barrier against oxidation and corrosion is an issue in many production contexts. The use of ferrous and non-alloy steels is typical for manufacturers of:

In order to guide the user in choosing the most suitable solution, we have classified temporary protectors on the basis of the following characteristics:

Discover the solutions for the protection of metal semi-finished products, for handling, testing, storage and transport. Reduce costs related to non-conformities and discover all the fundamental measures to limit oxidation and corrosion in all phases of the production process:

Find out how we solved problems similar to those of your project.

HEAD OFFICE:

Macon Research Srl

Via Santa Lucia, 8/D

36056 Tezze sul Brenta (VI)

Tel.+39 0424.57.39.66

Fax.+39 0424.57.39.66

Mail: info@maconresearch.com

ADMINISTRATIVE OFFICE:

Macon Research Srl

Via L. Tolstoj, 43/O

20098 San Giuliano Milanese (MI)

Tel.+39 02.98.24.41.61

Fax.+39 02.98.24.4161

Mail : info@maconresearch.com

The data contained in this catalogue are based on our general experience and knowledge at the time of publication and are intended to provide the reader with technical information about any possible uses. This information does not, however, constitute an assurance as regards product characteristics in relation to specific cases. We recommend that you request an interview with our consultants. We would be happy to provide you with samples.