Do you want to ensure the smooth operation of your components at temperatures above 250° C?

Does your product or that of your customers require superior durability and performance?

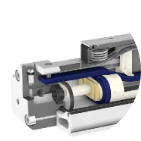

In any mechanical component such as geared motors, bearings, hinges, valves or pneumatic cylinders, thermal deterioration of the lubricating oil or grease that surrounds them can cause a sequence of rapid destructive in your design.

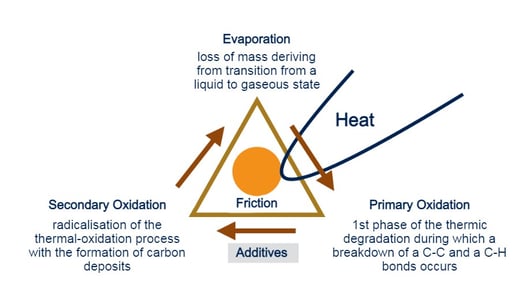

The impact of heat on the lubricating film can have two sources:

Even at temperatures as low as 100° C, heat can have devastating effects on your mechanical device due to a reduced thickness of the active lubrication film, which under normal conditions is equal to the diameter of a human hair! Its thermo-degradation rapidly reduces efficiency and kinematic life.

The process of thermal degradation of a lubricating grease is progressive and unstoppable. Yet, the choice of a thermally-stabilised lubricant can make all the difference in ensuring the durability and performance required by the market.

The degradation process occurs as follows:

The most obvious consequences of malfunctioning due to high operating temperatures can be translated into a sequence of concatenated and successive phenomena:

Maconsynth GT1/B

Grasso lubrificante a base di idrocarburo sintetico per cilindri pneumatici senza stelo

Pneugrease HTS

Grasso lubrificante a base di polidimetilsilossano per cilindri a basso attrite risparmio energetico

Maconsynth Retrac 400

Grasso lubrificante a base sintetica per cilindri pneumatici con anelli di tenuta in EPDM

Maconsynth GT1/B

Grasso lubrificante a base di idrocarburo sintetico per cilindri pneumatici senza stelo

Pneugrease HTS

Grasso lubrificante a base di polidimetilsilossano per cilindri a basso attrite risparmio energetico

Maconsynth Retrac 400

Grasso lubrificante a base sintetica per cilindri pneumatici con anelli di tenuta in EPDM

Ultragrease ATOX 2

Grasso lubrificante base PAO omologato per contatto accidentale con alimento

HEAD OFFICE:

Macon Research Srl

Via Santa Lucia, 8/D

36056 Tezze sul Brenta (VI)

Tel.+39 0424.57.39.66

Fax.+39 0424.57.39.66

Mail: info@maconresearch.com

ADMINISTRATIVE OFFICE:

Macon Research Srl

Via L. Tolstoj, 43/O

20098 San Giuliano Milanese (MI)

Tel.+39 02.98.24.41.61

Fax.+39 02.98.24.4161

Mail : info@maconresearch.com

The data contained in this catalogue are based on our general experience and knowledge at the time of publication and are intended to provide the reader with technical information about any possible uses. This information does not, however, constitute an assurance as regards product characteristics in relation to specific cases. We recommend that you request an interview with our consultants. We would be happy to provide you with samples.