Amongst synthetic lubricant solutions, fluorinated oils and greases are by far the most effective and durable barrier to protect against the deterioration of numerous mechanical kinematics under extreme operating conditions.

First introduced in the military and aerospace sectors, fluorinated oils or perfluoroalkylethers are linear or multi-branched polymers composed entirely of carbon, oxygen and fluorine. They are colourless, odourless and even totally inert to many chemical agents, including oxygen. They are compatible with many materials and remain fluid, providing unsurpassed lubricating properties over a broad range of operating temperatures.

Fluorinated oils belonging to the family of synthetic lubricating oils are distinguished by their structure into:

Fluorinated oils (PFPEs) are the precursors of fluorinated greases whose lubricating power is further enhanced by thickeners, solid lubricants (PTFE) and additives to improve rheological and anti-friction properties, in order to allow them to be utilised in application contexts where fluorinated oil alone would not provide adequate performance, such as for the lubrication of rolling bearings or where there is a need for greater adherence to friction zones. Compared to oils, fluorinated greases possess superior:

Unsurpassable thermal limits! Should the operating temperatures of a mechanical device be continuously below -80° C or constantly above 220° C, only with a fluorinated oil or grease will it be possible to guarantee constant hydrodynamic lubrication and, consequently, significantly longer re-lubrication times, being up to 10 times longer than with a mineral lubricant, resulting in drastically-reduced maintenance costs.

Fluorinated greases and oils are commonly used in the automotive, military aerospace, nuclear and all application contexts in which mechanical devices have to operate under critical thermal (low or high operating temperatures) or chemical conditions, including:

As demonstrated by the Noack Volatility Test at 250° C, fluorinated oils (PFPE) show significantly lower evaporation loss than all other synthetic oils at the same molecular weight and viscosity.

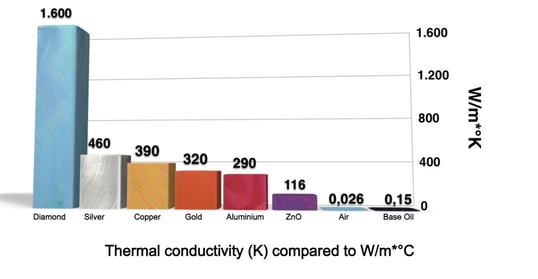

Synthetic lubricating greases and oils with a fluorinated composition are also preferred over those of a mineral or petroleum nature where:

HEAD OFFICE:

Macon Research Srl

Via Santa Lucia, 8/D

36056 Tezze sul Brenta (VI)

Tel.+39 0424.57.39.66

Fax.+39 0424.57.39.66

Mail: info@maconresearch.com

ADMINISTRATIVE OFFICE:

Macon Research Srl

Via L. Tolstoj, 43/O

20098 San Giuliano Milanese (MI)

Tel.+39 02.98.24.41.61

Fax.+39 02.98.24.4161

Mail : info@maconresearch.com

The data contained in this catalogue are based on our general experience and knowledge at the time of publication and are intended to provide the reader with technical information about any possible uses. This information does not, however, constitute an assurance as regards product characteristics in relation to specific cases. We recommend that you request an interview with our consultants. We would be happy to provide you with samples.