The smooth operation of a rolling bearing, a chain, a gear motor or any mechanical device already at -20° C and above cannot occur without a specific low-temperature lubricant solution.

The film of lubricant must provide the best compromise between the lowest possible viscous friction and the lowest possible frictional loss due to wear under all operating conditions.

Depending on its consistency (oil, grease or paste), a lubricant is composed of varying degrees of the following elements:

The main constituent directing and characterising the evolution of the lubricant's behaviour at low temperatures is the base oil that, depending on compositions, is present in percentages usually above 60% by weight.

The materials and parts that comprise an electro-mechanical device are, like lubricants, affected by temperature. Depending on their composition, plastics, metals, rubbers or composites can undergo one or more of the following alterations:

Once the minimum operating temperature of a mechanical device has been established, two parameters must be accurately identified for the correct formulation of the lubricant able to protect during operation:

Viscosity identifies the internal friction of a lubricating fluid and thus its resistance to sliding. The viscosity of an oil increases with decreasing temperature and is measured in cSt (centistokes) or cPs (centipoises). It is essential that its value at minimum operating temperature does not exceed the critical threshold, which would cause an excessive increase in friction.

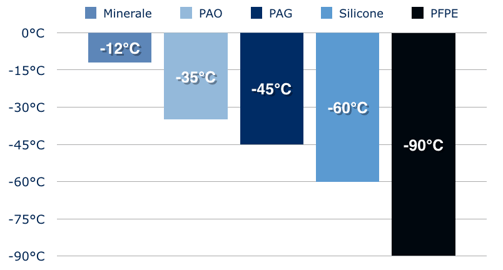

Base oils used in the formulation of industrial lubricants can be divided into two categories:

Mineral oils are those obtained by refining and distillation of crude oil, being cheap and unable to perform particularly well at low temperatures Belonging to the family of synthetics are oils obtained by direct synthesis through chemical reactions and processes. Synthetic oils provide superior performance at low temperatures, as shown in the graph comparing freezing points at the same viscosity.

If we imagine the lubrication of a rolling bearing operating at up to -50° C, it is natural to think that the choice of base oil cannot fall to a grade with a mineral composition!

Maconsynth GT1/B

Grasso lubrificante a base di idrocarburo sintetico per cilindri pneumatici senza stelo

Pneugrease HTS

Grasso lubrificante a base di polidimetilsilossano per cilindri a basso attrite risparmio energetico

Maconsynth Retrac 400

Grasso lubrificante a base sintetica per cilindri pneumatici con anelli di tenuta in EPDM

Ultragrease ATOX 2

Grasso lubrificante base PAO omologato per contatto accidentale con alimento

Maconsynth GT1/B

Grasso lubrificante a base di idrocarburo sintetico per cilindri pneumatici senza stelo

Pneugrease HTS

Grasso lubrificante a base di polidimetilsilossano per cilindri a basso attrite risparmio energetico

Maconsynth Retrac 400

Grasso lubrificante a base sintetica per cilindri pneumatici con anelli di tenuta in EPDM

Ultragrease ATOX 2

Grasso lubrificante base PAO omologato per contatto accidentale con alimento

HEAD OFFICE:

Macon Research Srl

Via Santa Lucia, 8/D

36056 Tezze sul Brenta (VI)

Tel.+39 0424.57.39.66

Fax.+39 0424.57.39.66

Mail: info@maconresearch.com

ADMINISTRATIVE OFFICE:

Macon Research Srl

Via L. Tolstoj, 43/O

20098 San Giuliano Milanese (MI)

Tel.+39 02.98.24.41.61

Fax.+39 02.98.24.4161

Mail : info@maconresearch.com

The data contained in this catalogue are based on our general experience and knowledge at the time of publication and are intended to provide the reader with technical information about any possible uses. This information does not, however, constitute an assurance as regards product characteristics in relation to specific cases. We recommend that you request an interview with our consultants. We would be happy to provide you with samples.