The lubrication of pneumatic valves is based on two fundamental principles:

Ring seals in pneumatic valves play the fundamental role of isolating pressure chambers in a dynamic environment that is unbalanced, tending towards higher operating frequencies and speeds along with shorter strokes than in pneumatic cylinders.

Although compressed air circuits are equipped with an oil lubrication system (to help reduce sliding friction of air shut-off and actuating components), market demands are geared more towards greater durability and reliability, with particular attention to the choice of lubricating grease to be used between the gasket and valve body.

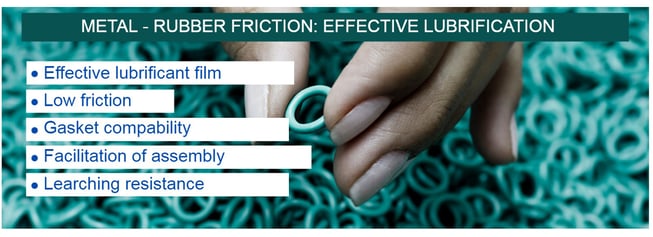

In the absence of a homogeneous lubricating film, O-rings, seals and gaskets deteriorate rapidly. For this reason, it is necessary to encase them with a lubricating grease designed to:

The guarantee of smooth valve operation can only be achieved by checking the compatibility of the lubricant and seal material.

The rubber-metal coefficient of friction is amongst the highest there is. Whilst this condition, together with the hardness value of the gasket, is set by the designer to ensure the "sealing effect", it also raises a potential threat of wear.

The choice of seal-body lubricating grease in a pneumatic valve is subject to an analysis of the application context and the tribological system as a whole, involving:

The most commonly-used materials for the manufacture of gaskets in pneumatic valves are chosen according to the service and application context, such as:

The risks of interaction between lubricant and seal should always be assessed beforehand to prevent seals from losing their original mechanical properties.

This presentation deals with the case of EPDM seals in contact with mineral oils and PAO and the catastrophic consequences that this combination can generate.

Special attention must also be paid to NBR gaskets, which are usually suitable for contact with mineral lubricating greases or PAO. However, there are some formulations that tend to increase their volume and hardness, causing valves to block!

Let us analyse the component to determine the purpose of the lubricant. We evaluate materials, the gases contains within, the thermal operating range, the coefficient of friction, the type of load to which it is subjected, the speed and dynamic operating environment.

We formulate an initial composition and, thanks to innovative rapid prototyping, guarantee a test sample in less than three weeks to verify functionality. We continue with successive formulations until your goal is achieved.

HEAD OFFICE:

Macon Research Srl

Via Santa Lucia, 8/D

36056 Tezze sul Brenta (VI)

Tel.+39 0424.57.39.66

Fax.+39 0424.57.39.66

Mail: info@maconresearch.com

ADMINISTRATIVE OFFICE:

Macon Research Srl

Via L. Tolstoj, 43/O

20098 San Giuliano Milanese (MI)

Tel.+39 02.98.24.41.61

Fax.+39 02.98.24.4161

Mail : info@maconresearch.com

The data contained in this catalogue are based on our general experience and knowledge at the time of publication and are intended to provide the reader with technical information about any possible uses. This information does not, however, constitute an assurance as regards product characteristics in relation to specific cases. We recommend that you request an interview with our consultants. We would be happy to provide you with samples.