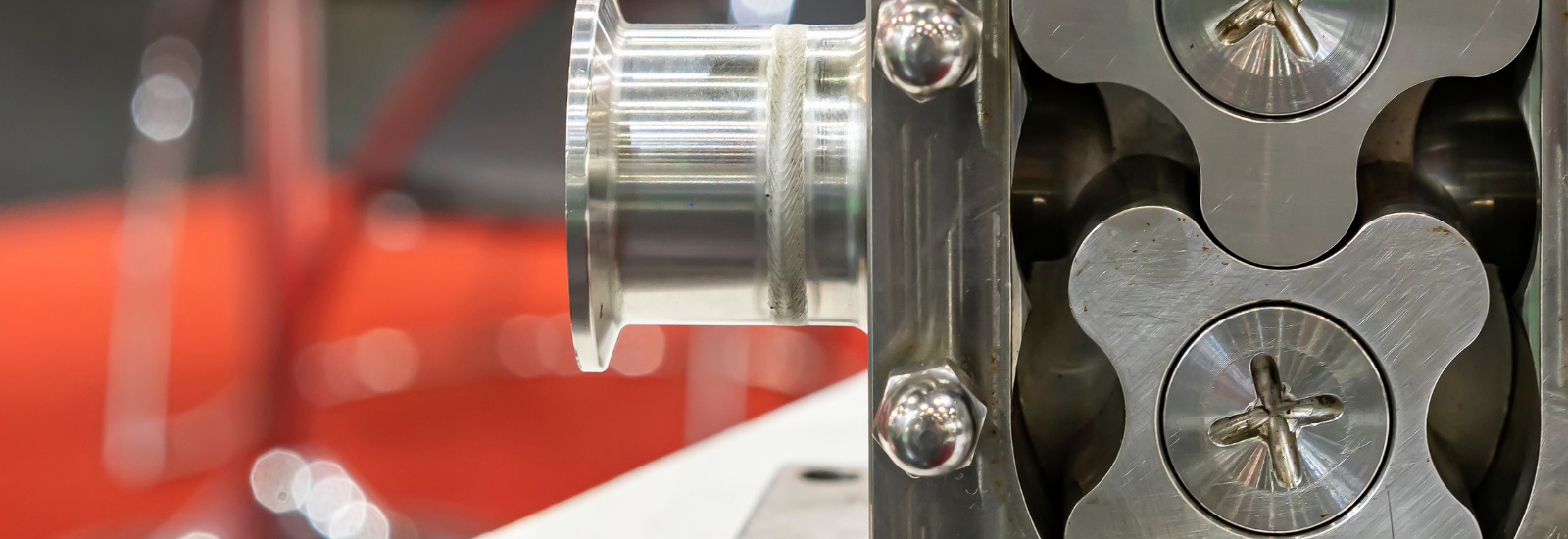

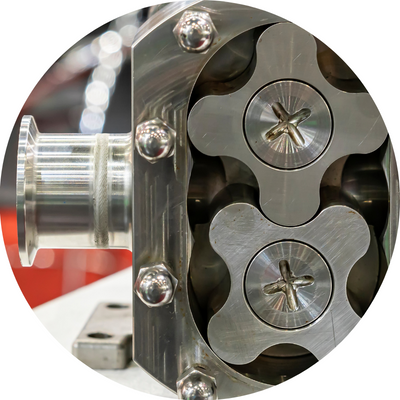

Vacuum and ultra-vacuum pumps are crucial components in a variety of industrial and scientific sectors. Their efficiency and reliability largely depend on correct lubrication. Lubrication plays a fundamental role by fulfilling several key functions:

Key points of a lubricating oil for vacuum and ultra-vacuum pumps:

A vacuum pump lubricating oil requires a targeted formulation to meet a range of essential criteria; no detail in its composition must be overlooked:

High vacuum: from 10-3 mbar to 10-7 mbar

Ultra vacuum from: less than 10-7 mbar

Why use a custom lubricating oil based on your design?

In the ultravacuum sector, there are particularly critical application contexts that require optimal and specific performance from pumping technology, where customized lubrication plays a fundamental role. Here are some examples:

In all these contexts, adequate and customized lubrication of vacuum pump oil is crucial. Choosing an oil specific to your unique operating conditions and application requirements not only ensures optimal performance is maintained but also results in significant benefits in terms of equipment life and reliability.

We analyze the component to identify the purposes of the lubricant. We evaluate materials, the gases that contain it, the operating temperature range, the friction coefficient, the type of load to which it is subjected, speed and dynamic context of operation.

We formulate a first composition and, thanks to the innovative rapid prototyping, we guarantee a test sample to verify the functionality in less than 3 weeks. We continue with subsequent formulations until your goal is achieved.

Once the ideal formulation has been identified, we are able to reproduce it exactly even in small production batches starting from 40 kg. Thanks to a versatile, scalable and replicable system over time, we fulfill all your supply requests.

SEDE LEGALE

Macon Research Srl

Via Santa Lucia, 8/D

36056 Tezze sul Brenta (VI)

Tel.+39 0424.57.39.66

Fax.+39 0424.57.39.66

Mail: info@maconresearch.com

SEDE AMMINISTRATIVA

Macon Research Srl

Via L. Tolstoj, 43/O

20098 San Giuliano Milanese (MI)

Tel.+39 02.98.24.41.61

Fax.+39 02.98.24.4161

Mail : info@maconresearch.com

I dati contenuti nel presente sito web si fondano sulle nostre esperienze e conoscenze generali al momento della pubblicazione e hanno lo scopo di fornire al lettore tecnicamente esperto indicazioni in ordine ai possibili impieghi. Queste informazioni non costituiscono però assicurazioni riguardo alle caratteristiche dei prodotti in relazione a casi specifici. Vi raccomandiamo di richiedere un colloquio con i nostri consulenti. Saremo lieti di mettere a vostra disposizione campioni per l’esecuzione di prove.