Statistics make it very clear for the designer: 36% of premature damage or sudden bearing failures are caused by incorrect lubrication, especially in cases where:

Rolling bearings, by virtue of their versatility and centrality in the design of industrial machines, can involve predictive periodic maintenance or lubricant replacement.

In both cases, synthetic lubricants are preferable to petroleum-derived mineral lubricants since they guarantee a higher lubricant film resistance and longer maintenance cycles.

A careful analysis of the operating and boundary conditions of the rolling bearing is the starting point for selecting the most suitable synthetic lubricating grease, involving:

The design of a rolling bearing is the first requirement to be taken into account when choosing a lubricating oil or grease. In particular, the absence of protective shields – such as in the case of shaft bearings in axle reduction units – presupposes that the lubricant applied to the gear chamber also provides wear protection for the bearing itself.

Thus, rolling bearings have the dual need to be lubricated and protected. It follows that the choice of the right lubricant must balance two opposing risks:

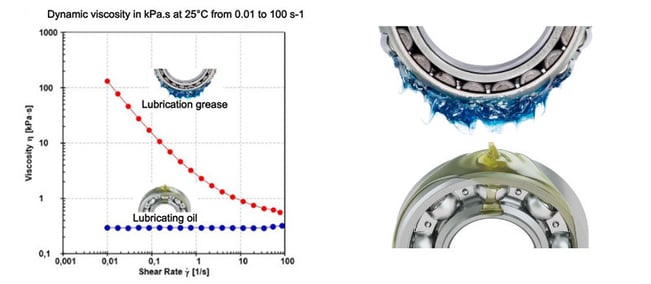

The use of a grease, as opposed to an oil, favours adhesiveness yet also raises the problem of increased friction during bearing rotation (especially in the transient start-up phase of rotation), which must therefore be regularised by adjusting the viscosity of the base oil.

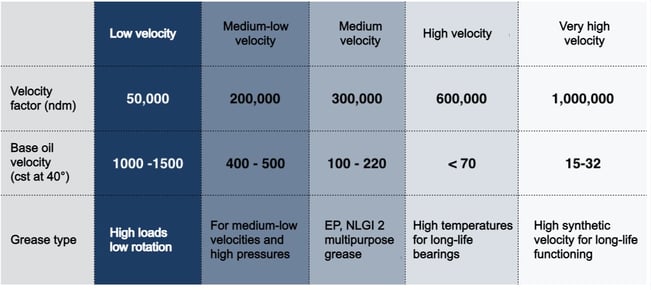

The ideal level of dynamic viscosity in a bearing lubricant is calculated from the velocity factor – the numerical value obtained by multiplying the bearing's maximum rotational speed (rpm, as indicated by the bearing manufacturer) by its average diameter in dm. The higher the declared rotational velocity of the bearing, the lower the viscosity of the lubricant must be.

It goes without saying that standardised lubricants will never completely satisfy the velocity factor of a bearing, which can be achieved by designing and developing a customised solution.

Let us analyse the component to determine the purpose of the lubricant. We evaluate the materials, the gases contains within, the thermal operating range, the coefficient of friction, the type of load to which it is subjected, the velocity and dynamic operating environment.

We formulate an initial composition and, thanks to innovative rapid prototyping, guarantee a test sample in less than three weeks to verify functionality. We continue with successive formulations until your goal is achieved.

HEAD OFFICE:

Macon Research Srl

Via Santa Lucia, 8/D

36056 Tezze sul Brenta (VI)

Tel.+39 0424.57.39.66

Fax.+39 0424.57.39.66

Mail: info@maconresearch.com

ADMINISTRATIVE OFFICE:

Macon Research Srl

Via L. Tolstoj, 43/O

20098 San Giuliano Milanese (MI)

Tel.+39 02.98.24.41.61

Fax.+39 02.98.24.4161

Mail : info@maconresearch.com

The data contained in this catalogue are based on our general experience and knowledge at the time of publication and are intended to provide the reader with technical information about any possible uses. This information does not, however, constitute an assurance as regards product characteristics in relation to specific cases. We recommend that you request an interview with our consultants. We would be happy to provide you with samples.