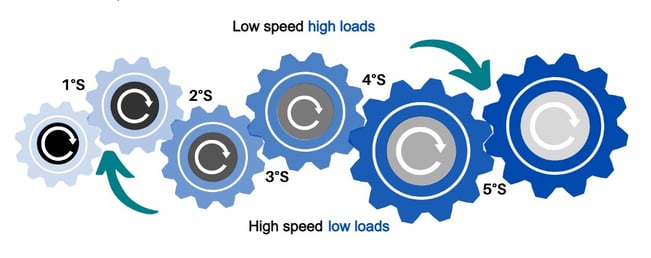

Gearmotors represent one of the most complex cases of mechanical lubrication, needing a lubricant capable of ensuring the correct separation of friction surfaces in a context of variable dynamic along the chain of motion transfer where:

A geared motor is thus a heterogeneous tribological system. At different points in the transmission (as seen in the 5-stage model shown above), very different operating conditions occur. Adequate lubrication must be able to intercept such at their maximum and minimum functioning, with:

The main threat of irregular gearbox operation, along with mechanical wear, is the rise in temperature often caused by inadequate lubrication.

Both types of friction coexist in a gearbox: sliding and rolling. In instances of dominant sliding friction, such as in helical-worm wheel couplings, where a "rapid" reduction in rotational speed in favour of transmitted torque is required, the lubricant composition must be balanced with the use of specific components:

The choice of lubricant consistency is mainly related to the application context and the need to remove heat during operation in order to avoid:

The choice of oil or grease solution to be used affects both the design of the containment chamber and the method of lubrication.

Let us analyse the component to determine the purpose of the lubricant. We evaluate the materials, the gases contains within, the thermal operating range, the coefficient of friction, the type of load to which it is subjected, the speed and dynamic operating environment.

We formulate an initial composition and, thanks to innovative rapid prototyping, guarantee a test sample in less than three weeks to verify functionality. We continue with successive formulations until your goal is achieved.

HEAD OFFICE:

Macon Research Srl

Via Santa Lucia, 8/D

36056 Tezze sul Brenta (VI)

Tel.+39 0424.57.39.66

Fax.+39 0424.57.39.66

Mail: info@maconresearch.com

ADMINISTRATIVE OFFICE:

Macon Research Srl

Via L. Tolstoj, 43/O

20098 San Giuliano Milanese (MI)

Tel.+39 02.98.24.41.61

Fax.+39 02.98.24.4161

Mail : info@maconresearch.com

The data contained in this catalogue are based on our general experience and knowledge at the time of publication and are intended to provide the reader with technical information about any possible uses. This information does not, however, constitute an assurance as regards product characteristics in relation to specific cases. We recommend that you request an interview with our consultants. We would be happy to provide you with samples.