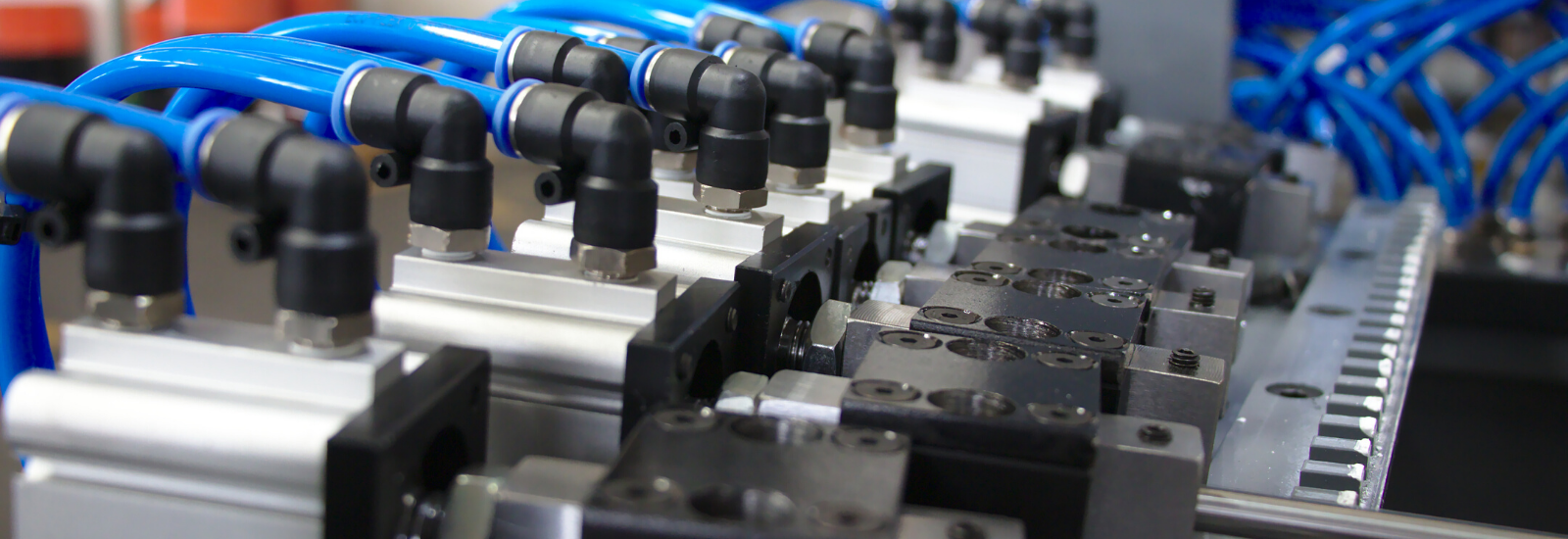

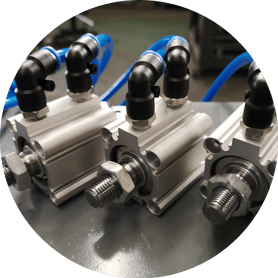

Pneumatic cylinders are the most common actuators in compressed air systems. They are the primary means of pushing slides, lifting weights, clamping workpieces, powering equipment, removing workpieces and actuating levers.

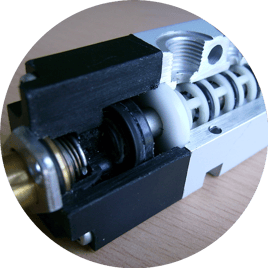

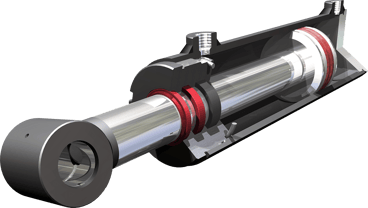

The performance and service life of a pneumatic cylinder are conditioned by the integrity of the gaskets separating the pressure chambers. Their integrity is ensured by proper lubrication and assembly during fitting.

They are distinguished by:

The sealing ring or gasket makes the most important contribution to the life and durability of the pneumatic cylinder, where the role of the lubricating grease can be decisive. What are the benefits of proper lubrication?

The lubrication of gaskets introduces an important yet often overlooked component concerning the potential chemical attack and consequent change in the structural properties of the compound, which can be translated into changes in size, hardness and sealing power.

The variety of design solutions for pneumatic cylinders is very broad, with there being guided, rodless, double-acting or single-acting and magnetically-driven compact cylinders. The design requirements, and thus also the choice of lubricant grease, take into consideration:

Equally important are any limitations in the use of lubricating solutions dictated by the application context of the cylinder, such as:

One of the most insidious threats in the operating environment of a pneumatic cylinder, typical of rubber-metal sliding friction, is the jerking motion. Commonly referred to as stick-slip, this manifests through an irregular cylinder stroke pattern, especially when changing direction – an undesirable phenomenon and the cause of intermittent operation, frequently caused by inadequate lubrication.

Let us analyse the component to determine the purpose of the lubricant. We evaluate materials, the gases contains within, the thermal operating range, the coefficient of friction, the type of load to which it is subjected, the speed and dynamic operating environment.

We formulate an initial composition and, thanks to innovative rapid prototyping, guarantee a test sample in less than three weeks to verify functionality. We continue with successive formulations until your goal is achieved.

HEAD OFFICE:

Macon Research Srl

Via Santa Lucia, 8/D

36056 Tezze sul Brenta (VI)

Tel.+39 0424.57.39.66

Fax.+39 0424.57.39.66

Mail: info@maconresearch.com

ADMINISTRATIVE OFFICE:

Macon Research Srl

Via L. Tolstoj, 43/O

20098 San Giuliano Milanese (MI)

Tel.+39 02.98.24.41.61

Fax.+39 02.98.24.4161

Mail : info@maconresearch.com

The data contained in this catalogue are based on our general experience and knowledge at the time of publication and are intended to provide the reader with technical information about any possible uses. This information does not, however, constitute an assurance as regards product characteristics in relation to specific cases. We recommend that you request an interview with our consultants. We would be happy to provide you with samples.