Do you want to easily assemble rubber parts? Are the O-rings on your project damaged upon being mounted on the shaft? Have you tried any lubricant solutions before only to see the rubber swell, contract or lose its mechanical properties? Do you want a solution that helps with assembly then disappears altogether? Odourless, transparent and approved for food contact? Biodegradable? Then continue reading as we outline 5 reasons to choose an ad-hoc lubricant solution.

Facilitate assembly only

assembly + dynamic exercise?

Find out more

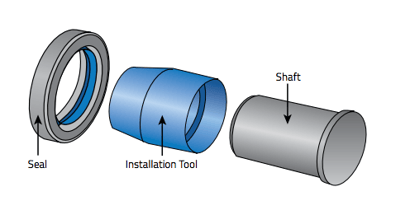

Seal rings and O-rings are necessary for the operation of a mechanical device. Their economic worth is small and insignificant compared to the valuable function they fulfil. However, their efficiency is vital and can considerably affect that of the mechanical component in which they are housed. However, it is quite common, such as when they are fitted on transmission shafts, for some of their "integrity" to be lost. In this article, we look at 5 fundamental aspects to consider if you want to assemble a seal with a "lubricating fluid". You will also discover the characteristics of the ideal lubricant solution depending on whether the seal performs a separation function in dynamic operation (e.g., pneumatic cylinders) or static operation (e.g., transmission shafts).

1) Compatibility with tyres

In this article we address the delicate issue of "interaction of lubricating fluids and rubber sealing elements", with particular attention to the types of materials, the functions of the seals and predictive incompatibility tests. If you want to avoid destroying your project altogether, it is advisable to evaluate a priori the potential interactions between the compounds and the lubricants used for assembly or for the lubrication of your gaskets. The following presentation highlights the reactions caused by prolonged contact between lubricating fluids of the same viscosity yet with different chemical composition, in contact with an EPDM gasket.

Download the pdf

Seal Lubricant Compatibility Guide

Download the pdf

2) Durability on areas in friction

A lubricating fluid must reduce the coefficient of friction. That’s obvious. However, even more important is its ability to form a thin and homogeneous lubricating film that remains between the seal and the rotating shaft in a state of sliding friction at the moment of overlap. A seal ring performs the following functions:

- Oil containment, as in a gearmotor lubricated with oil or fluid grease

- Protective shield for contaminants (particulate, dust)

- Both of the above

In some conditions, the seal ring – due to a need to support a high counter pressure – can be equipped with a containment spring to increase the pressing action on the shaft and the friction between rubber and metal. In such conditions, the lubricating solution for the assembly must have further persistence properties on the points of greatest stress in terms of:

- Adhesiveness, to avoid being "undermined" by the friction surfaces

- Impermanence – once having exercised the function of adjuvant for the assembly, the compound must "evaporate" in order not to favour the expulsion of the seal in operation

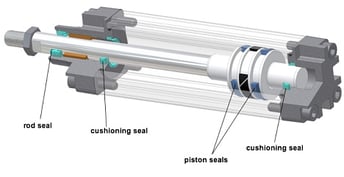

The condition is different if a contribution of the lubricating grease is necessary following assembly operations, such as for a gasket on a cylinder or a pneumatic valve. In such cases, it is advisable to evaluate the persistence of the lubricant over time under the operating conditions of the component, namely:

- Sliding speed of the friction surfaces

- Surface pressures between sealing ring and sliding tube

- Working temperature range

3) Preventing damaging to the sealing profiles

The profile of a seal ring has a fundamental function: to separate. Its premature damage inevitably leads to early malfunctions, with consequent increases in maintenance costs:

- Oil loss (geared motors)

- Efficiency reduction (pneumatic cylinder)

- No pressure isolation of the chambers (hydraulic actuator)

As seen, damage can occur during the assembly or during operation owing to extensive roughness of the surface of the rotation shaft or an imperfect alignment. In such cases, the presence of solid lubricants such as boron nitride or PTFE (Teflon) in the formulation can guarantee optimal operation even after prolonged use, reducing the coefficient of friction locally by "filling" the micro roughness of the surfaces.

4) Do not compromise the mechanical seal function

The use of a "traditional" grease or lubricating oil guarantees a reduction in the coefficient of friction. All the time. If it is merely necessary to facilitate assembly, it is advisable to check that following insertion, misalignment or expulsion of the gasket in operation is not enabled.

The ideal lubricant solution must:

- Facilitate insertion

- Evaporate from the friction point

- Leave a residue that can hold the seal in place

5) Enhance the sealing effect

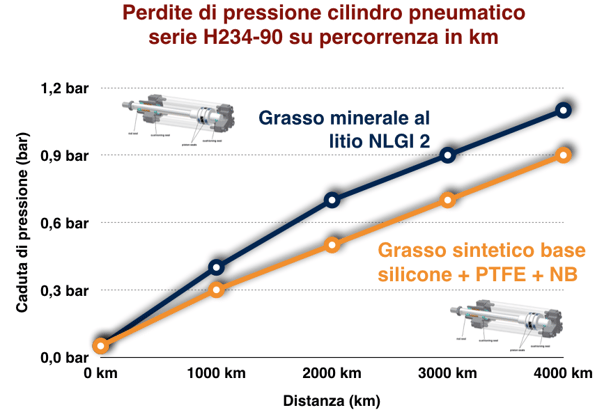

A lubricating grease can help not only improve assembly and increase life but also better the sealing effect of a gasket. The right combination of viscosity of the base oil used in the formulation of the grease, the presence of solid lubricants and a thickener with high polarity favour the formation of a homogeneous film capable of filling the depressions present on the friction surfaces, thus reducing the residual room for leakage of the intercepted fluid (gas or fluid) contained in the separation chambers. Below, we observe how two identical seal rings mounted on pneumatic cylinders show a different degree of decay depending on the lubricant equipped:

- NLGI lithium mineral lubricating grease 2

- Synthetic silicone-based grease + PTFE + NB

Pressure losses of pneumatic cylinder series H234-90 over distance in km

Pressure drop (bar)

Distance (km)

NLGI lithium mineral grease 2

PTFE + NB silicone-based synthetic grease

What is your current state? What is the function of the lubricant in your project?