Find the right compromise between low friction and adhesiveness in lubrication!

Improving the adhesion of the lubricant to the friction components and reducing energy absorption is not easy to achieve, only through an accurate formulation of the lubricating grease can you guarantee the prolonged stay in correspondence with the fast gears of your motor-reducer, without unnecessarily increasing energy absorption.

Knowing the dynamic viscosity and adhesiveness of your lubricant is essential to optimize the performance of numerous mechanical components:

- Gearboxes

- Rolling bearings

- Male or ball valves

- Pneumatic cylinders and valves

- Kinematics in metal / metal sliding friction

- Kinematics in metal / rubber sliding friction

- Kinematics in metal / plastic sliding friction

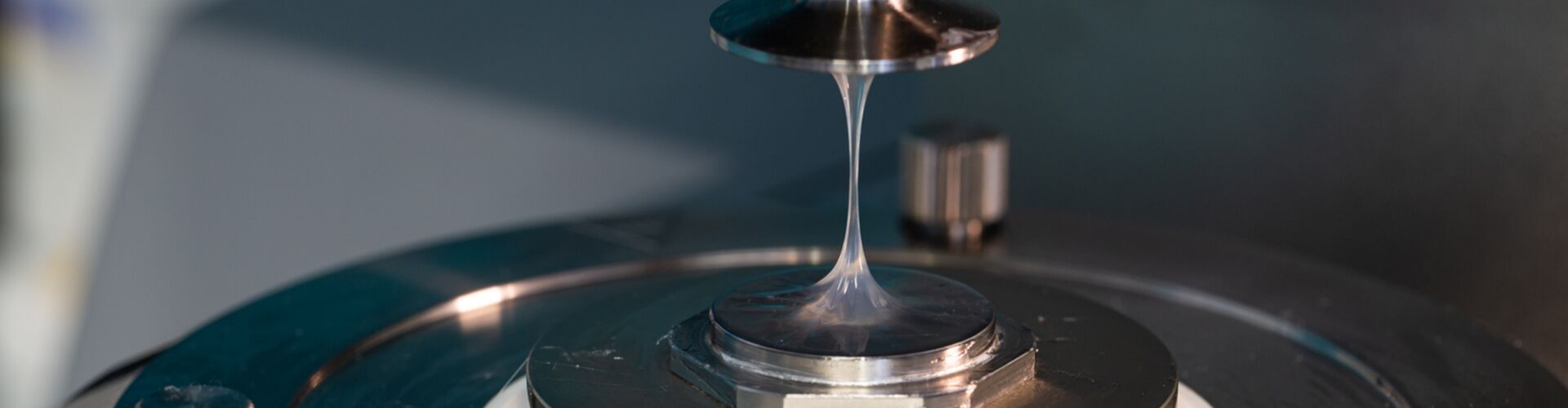

In the Macon Research laboratories we analyze the adhesive, cohesive and filamentary power of your lubricating grease with a specific test performed with Anton Paar MCR 102 precision rotational rheometer.

Why is it useful to know the adhesiveness and dynamic viscosity of a lubricating grease?

Through the analysis of adhesiveness and dynamic viscosity at constant temperature it is possible to:

- Characterize the viscous structure and its lubricating power

- Evaluate the dynamic friction at low, medium and high speeds

- Compare and optimize the wording based on the context of operation

- Reduce the amount of lubricant used

- Evaluate the lubrication power from -50 to + 250 ° C