Low temperatures affect physical and mechanical properties of materials and can determine premature failure of mechanical devices. Why?

Design of a mechanical devices must take into account the lower working temperature limit not only for materials but also for the lubricating properties, how many cycles and and which temperature: -50 ° C, -40 ° C, -30 ° C, -20 ° C ?

Materials components reactions are not always predictable at low temperature conditions. The same may happen for lubricating fluids, which may work properly at room temperature but suffer once temperature drop below zero. Scenario can get worst if component at frozen conditions tend to last longer. This the reason why fluids lubrincant must be formulated properly.

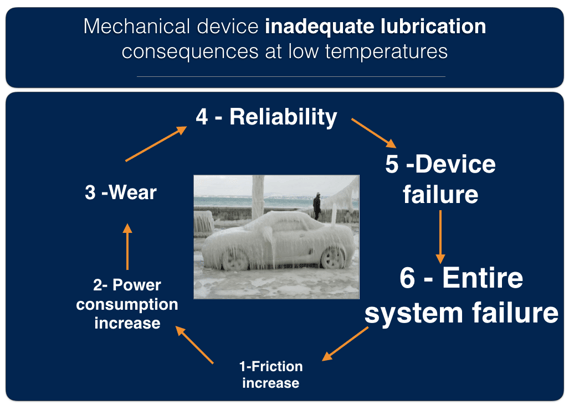

The figure is self explanatory, considering the huge number of mechanical device that are working inside, it is really important to deliver in all conditions a very fluid lubricating film: wheel bearing, brake hydraulic cylinder, gearshift, brake switches, window lifter mechanism......

Most common effects:

Material deformation: contractions of metals and polymers (elastomers, plastics and composites)

Embrittlement: decrease of the elastic properties of polymers, some elastomers such as nitrile rubber (NBR), if not reinforced with additives, become brittle and suffer permanent damage during low temperature working conditions.

Cohesion of sliding surfaces: cohesive effects can occour due to crystallization phenomena

Increase of static and dynamic friction coefficients, caused by dynamic viscosity increase of the lubricating fluids.

Change of mechanical properties of materials: elongation at break

Decay process caused by the unreliability of lubricating fluid to work properly in "cold" conditions is rather linear and characterized by a precise sequence of events:

Internal friction increase: resulting from the aggregation of the polymers at low temperatures, it produces an increase of the friction coefficient of the surfaces in mutual sliding, due to the greater force required to slide the fluid layers of the cold lubricating film.

Power consumption increase: it is necessary a greater supply of energy, enough to let device working properly.

Wear increase: friction increase determine wear, due to contact surface ratio increase, with loss of material necessary to maintain device integrity.

Reliability loss: in these conditions is no longer guaranteed the number of cycles originally originally expected from component design, negative contribution not expected, caused by low temperature unpredicted conditions will produce destructive effects.

Device failure: device does not work properly anymore, or starts more frequently functionality stand-by.

Entire system failure: if the device is a crucial part of a more complex system, such as the starter motor in a motor car, its functionality prevents the entire system to perform its function properly.

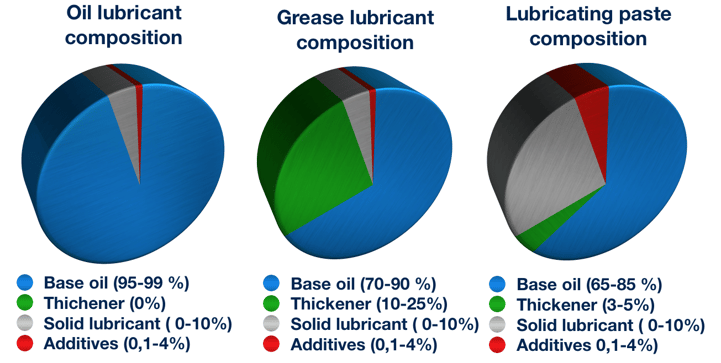

Lubricating fluids are essentially composed by 4 different elements:

Base oil

Thickener or soap

Solid lubrincants

Additives

Figure below shows the average % weight of each elements in oil, pastes and grease Base oil is always preponderant compared to the other constituents (65-99% by weight). For this reason it is essential to take into account at least two fundamental features that affect the same base oil performance at low temperatures:

Pour point

Viscosity temperature curve

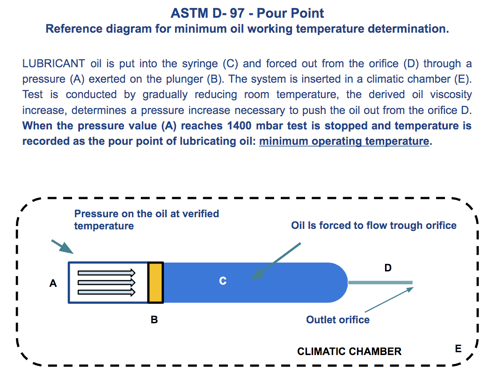

Pour point: from standard ASTM D-97 defines the minimum working temperature which allow the oil to "flow" under specific conditions. The figure shows a short description of the test

LUBRICANT oil is put into the syringe (C) and forced out from the orifice (D) through a pressure (A) exerted on the plunger (B). The system is inserted in a climatic chamber (E). The test is conducted by gradually reducing room temperature, the derived oil viscosity increase, determines a pressure increase necessary to push the oil out from the orifice D. When the pressure value (A) reaches 1400 mbar test is stopped and temperature is recorded as the pour point of lubricating oil: minimum operating temperature.

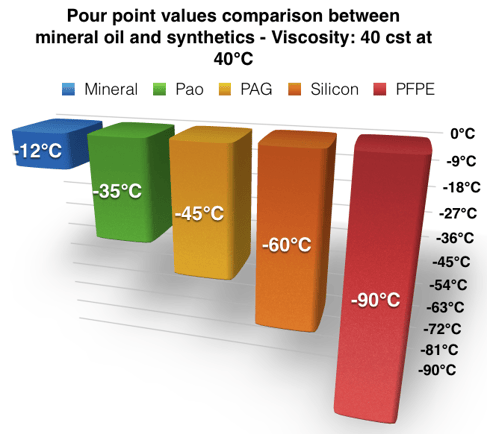

Figure below shows some pour point values of different base oil chemistry. kinematic viscosity value at 40 ° C is 46 cst. Difference between a mineral oil and other synthetic oils is self explanatory. This information is very important in design step of any mechanical device. If the minimum operating temperature is - 30 ° C it is not recommended a lubrication with mineral base oil which tend to lose its flow properties at -12 ° C

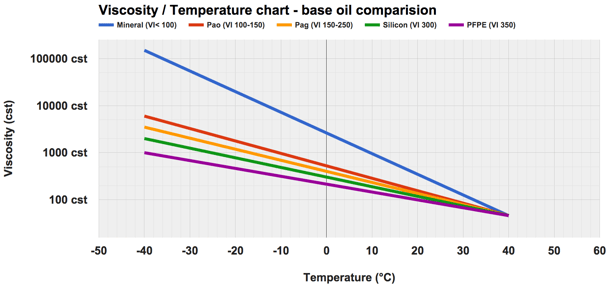

Viscosity temperature curve: kinematic viscosity variation with the temperature. Below some exaples of viscosity temperature curves. Synthetic base oil nature such as polyalphaolefin (PAO), polyglycol (PAG) and silicones, are much more stable (lower slope) compared to mineral oils (blue line high slope). Mineral oil viscosity values tend to increase greatly with temperature drop. Nowadays the greater part of lubricating fluids available on the market are still formulated from mineral base oils.

The following technical guide will analize 4 basic requirments to take into account when a low temperature lubricating fluid is necessary for your application. Download now !

HEAD OFFICE:

Macon Research Srl

Via Santa Lucia, 8/D

36056 Tezze sul Brenta (VI)

Tel.+39 0424.57.39.66

Fax.+39 0424.57.39.66

Mail: info@maconresearch.com

ADMINISTRATIVE OFFICE:

Macon Research Srl

Via L. Tolstoj, 43/O

20098 San Giuliano Milanese (MI)

Tel.+39 02.98.24.41.61

Fax.+39 02.98.24.4161

Mail : info@maconresearch.com

The data contained in this catalogue are based on our general experience and knowledge at the time of publication and are intended to provide the reader with technical information about any possible uses. This information does not, however, constitute an assurance as regards product characteristics in relation to specific cases. We recommend that you request an interview with our consultants. We would be happy to provide you with samples.