Water resistant grease: composition and applications

"Water compatibility of lubricating greases"

The search for the right lubricating grease for your business revolves around one critical consideration: what will its application scope be?

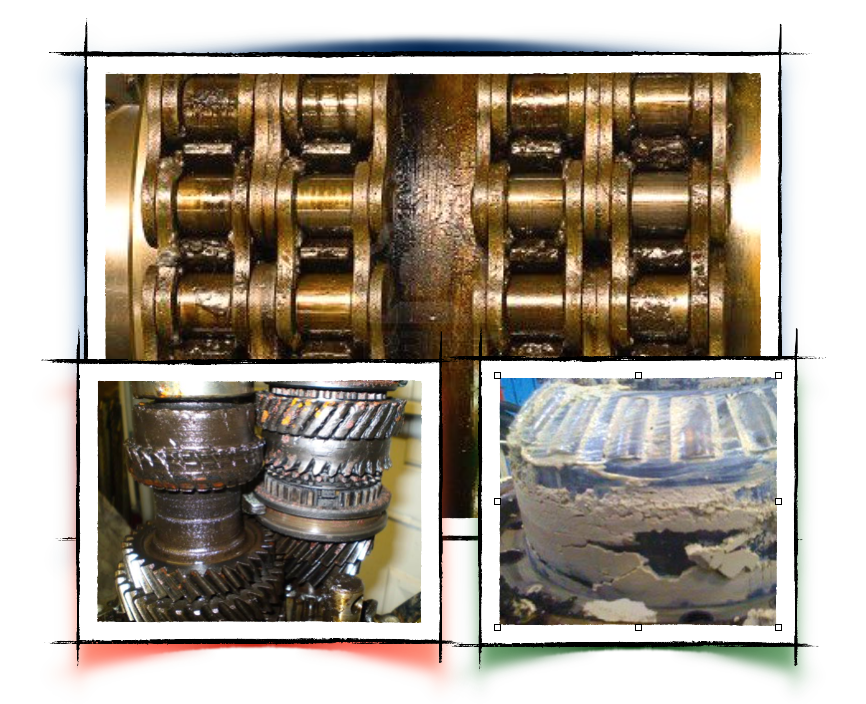

Greases are used for the lubrication and protection of mechanical parts as an alternative to or as a substitute for liquid lubricants, but as they are "pseudo-plastic" fluids, it is very important to study their characteristics well to be sure to have a proper water-resistant grease.

READ ALL