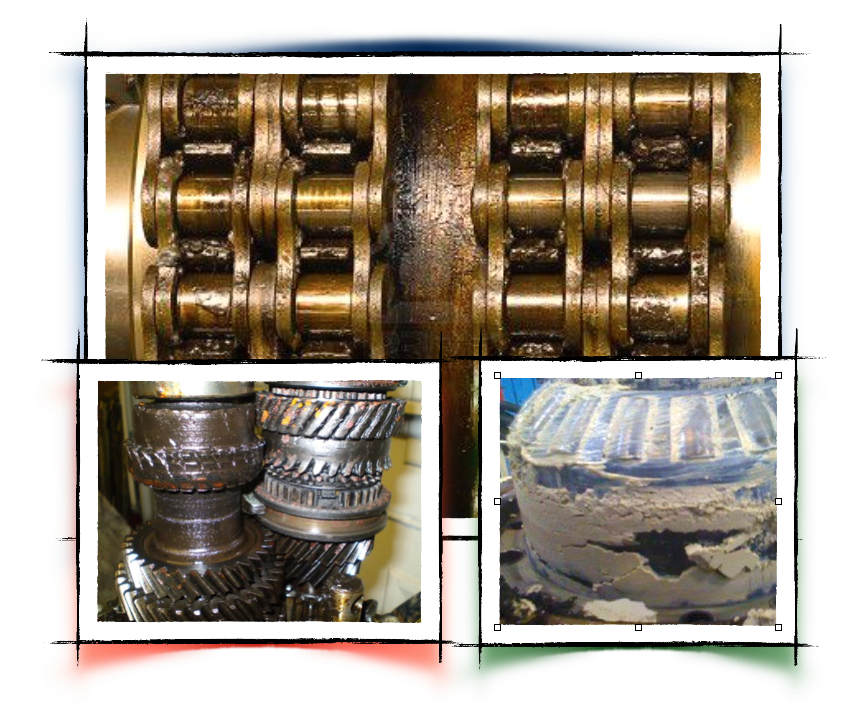

Have you ever seen a chain, bearing or gear with large areas of dry lubrication that ends up covered in a pasty residue of a different colour from the piece itself, that is sticky and devoid of any lubricating power? What are the possible causes? Are we sure that the maximum working temperature has not exceeded that declared in the Technical Datasheet of the Teflon® grease used as a lubricant in the application?

The variables in a tribological system are numerous, and difficult to predict – as is the case with thermal exposure cycles to which mechanical organs are subjected, for example. We have discussed in other articles on our blog just how critical it can be for a mechanical device to exceed the thermal capacity of the lubricating fluid that surrounds it and the sequence of the decay processes for the fluid and the device itself. In this article, we will talk about how it is possible to limit mechanical anomalies due to thermal stress with a high-temperature grease based on fluorinated oils.

How to ensure top performance with a high temperature grease

Fluorogrease 935Y

High temperature lubricating grease

100% synthetic lubricating grease for high temperatures extend the lubrication cycles and life of mechanical parts up to 280° C in continuous operation

1) High-temperature grease with 70% oil

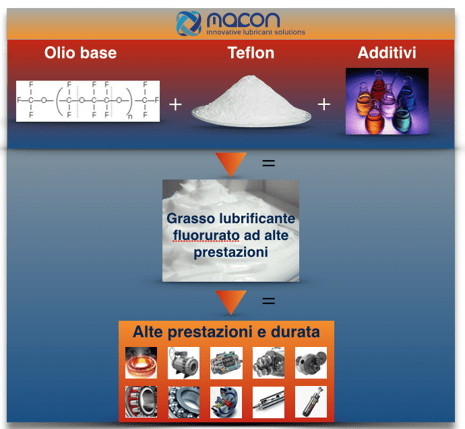

In consideration of the fact that at least 70% by weight of an industrial grease is made up of oil, a few words could be said about the family of synthetic oils that are most suitable for high-temperature applications: fluorinated oils. The structure of the polymer that constitutes this type of oil undergoes the processes of evaporation, thermo-degradation and carbonisation to a minimum, thus helping to keep the lubricating film active even when temperatures exceed 200° C.

The chemical-physical reasons that explain the thermal resistance of a fluorinated oil are rather complex but can be explained by the great chemical stability of the polymer thanks to the massive presence of "fluorine". Its presence helps to fortify chemical bonds and to limit the disturbing actions caused by thermal energy. Fluorinated lubricating oils are also thickened with Teflon® (PTFE) for transformation into lubricating greases. This also creates a strong synergy together with additives, guaranteeing excellent efficiency performance and superior durability in the mechanical devices that equip them.

Base oil + Teflon + Additives

= high-performance fluorinated lubricating grease

= high-performance and durability

2) Maximum working temperature and exposure time

One aspect that is often underestimated and which is reported in the technical specifications of lubricating greases is the maximum working temperature that the lubrication film can bear without any relation to the exposure time. It makes little sense to know that a lubricant can withstand up to 400° C without knowing the time it can stand such conditions before undergoing macroscopic decay processes. Is it necessary to foresee lubrication cycles? What if the mechanical part cannot be lubricated once it is put into operation?

Let's think, for example, of components in the automotive industry such as the starter motor, the window lifter gearmotor or the hydraulic control of a clutch. For obvious reasons, these devices cannot be re-lubricated during their operation, therefore their duration and correct functioning are linked to a first "correct" lubrication. So, is it possible to guarantee a lubricating film that is stable over time and functional to the thermal cycles to which the device must undergo? Of course it is! Below, we compare the % evaporations according to Noack's volatility. With this simple test, which consists in subjecting the base oil to a temperature of 250° C for 1 hour, the % losses by weight are detected.

This test is useful in focusing attention on the evaporation aspect, which represents the first critical factor that a lubricating oil has to face when the working temperatures increase. PFPE (fluorinated) oil represents the most stable solution and that with the lowest weight loss for the same viscosity.

Mineral PAO Ester Diester

Polyester Polyglycol Silicone PFPE

% loss in weight

The graph below compares lubricating oils of different chemical natures. Sustained uninterrupted exposure time from a mechanical device at rising temperatures up to mechanical failure (operating hours) is compared. Also in this case, there is a clear superiority of fluorinated formulations (PFPE) over mineral or synthetic ones of another nature.

Resistance of lubricating film based on the maximum continuous operating temperature

Hours of continuous operation

Temperature ° C

Mineral oil

PAO oil

PAG oil

Silicone oil

PFPE oil

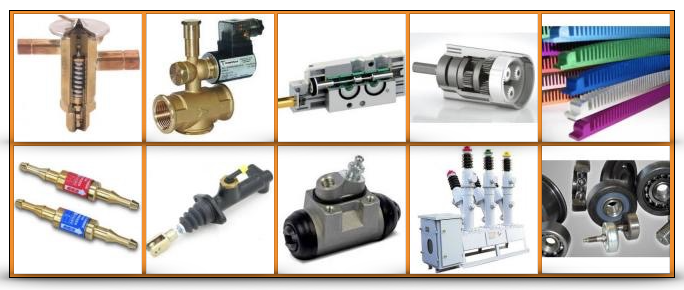

3) Applications of a fluorinated-based high-temperature grease

There are no application limits to their use, with the cost-benefit ratio being the only aspect to take into consideration. It is useful to perform an economic comparison between the use of a standard grease and a fluorinated grease to establish the actual "convenience".

We wrote about a successful example obtained by replacing a standard grease with a high-performance fluorinated-based lubricating grease. In the same article, economic details are reported and a real saving is documented by replacing a lubricating grease from 6 euro per kg with one of 300 euro. Here is a review of the main applications in which a fluorinated lubricating grease can be used:

- Bearings for transport chains overhead conveyors

- Bearings for corrugated cardboard machines

- Hydraulic controls for the automotive industry

- Brake caliper cylinders

- Double-glazing planetary gearboxes

- Pneumatic valves

- Lamination valves for air-conditioning systems

- Methane gas valves

- Safety valves for oxygen use

- High voltage switches in SF6 (sulfur hexafluoride)

- Thermal compund heat sink

4) Additional benefits

- Compatibility of plastics and elastomers - a total absence of swelling and variations in mechanical properties in the compounds making up the gaskets

- Use in an atmosphere with a high concentration of oxygen - fluorinated lubricating fluids are non-flammable, which allows them to be used where oxygen at high concentrations and pressures is intercepted

- Accidental contact with food - the fluorinated formulations are generally non-toxic and can be used where a potential accidental contact with food or semi-finished products used in food production cycles is envisaged

- High resistance to washout by organic fluids

If you want to learn more about the functional characteristics of a high temperature grease, download the Technical Datasheet or request a free sample directly.

Fluorogrease 935Y

High-temperature lubricating grease

100%-synthetic lubricating grease for high temperatures extend the lubrication cycles and life of mechanical parts up to 280° C in continuous operation