"We have reduced mechanical wear by 30% and doubled the number of effective manoeuvres just by replacing the lubricating grease."

These are the words of Giuseppe Ruggeri, head of the contactor project in the electromechanical division of Lovato Electric. We interviewed him to find out about the reasons behind and benefits obtained from completing the functionality tests with Maconpaste HP as a lubricant solution for reducing wear on the pin-bushing coupling in the contactor drive kinematics.

For over 90 years, LOVATO Electric has been designing and manufacturing low-voltage electrical components for industrial applications. Founded in 1922 in Bergamo, LOVATO Electric is a private company with over 250 employees Ever attentive to quality, LOVATO Electric has well understood how a lubricant suitable for the operating conditions can make all the difference in the kinematics of the electromechanical devices. In this article, we share their experience.

Maconpaste HP lubricating grease

- Reduces mechanical wear

- High load capacity

- Suitable for metal-metal couplings

- Excellent emergency lubrication

- Solid lubricants

Discover the main applications

Download the datasheet

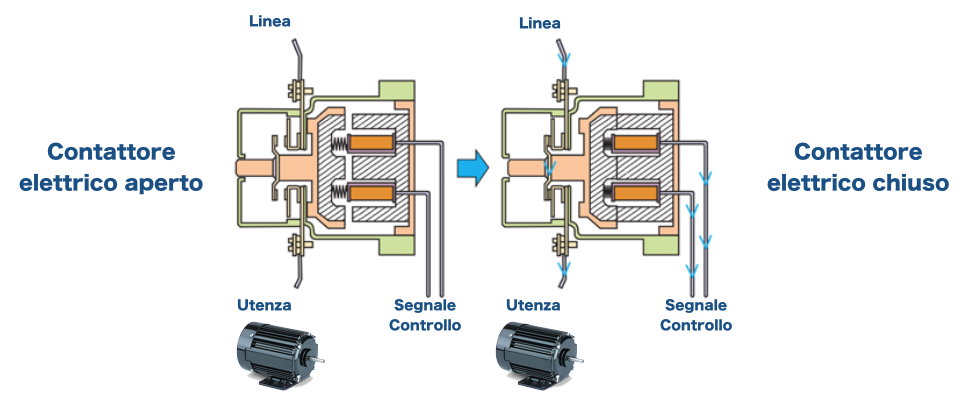

1) Principle of contactor operation

A contactor is an electromechanical device that serves to switch the passage of current to an electrical utility, upon the occurrence of certain conditions. It is made up of:

- An electrical part, where contact is made

- An electromagnet, responsible for switching

- An actuator controlled by the electromagnet, with the function of mechanical switching actuation, consists of levers and springs ready to discharge the pre-accumulated energy, in a very rapid time which can range from a few tenths of a second, as in the case in question, to a few hundredths of a second in smaller appliances.

A typical example of using a contactor is as a control device for an electric motor.

Electric meter open

Line, Utility

Control signal

Line, Utility

Electric meter closed

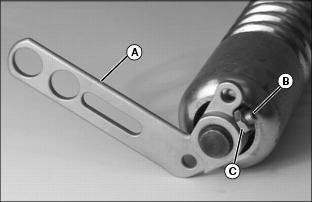

2) Parts in friction and lubrication

The most critical area subject to mechanical wear from friction and to be protected during operation is represented by the coupling of the steel shaft and the bronze support bushing, responsible for the vertical transmission of the contacts.

Due to the high sliding speeds and elevated working pressures, the heart of the drive is subject to considerable mechanical stress: the lightning-fast transition from a condition of rest to motion does not allow the formation of a fluid and homogeneous lubricating film.

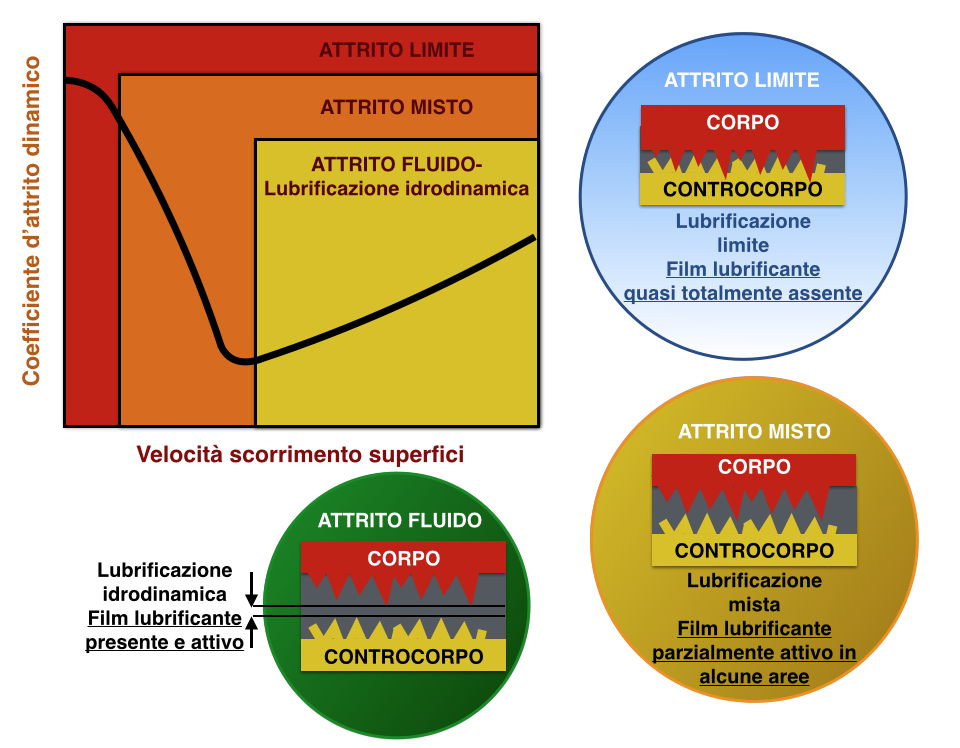

Dynamic coefficient of friction

Surface scrolling speed

LIMIT FRICTION

MIXED FRICTION

FLUID FRICTION - Hydrodynamic lubrication

LIMIT FRICTION - BODY - COUNTERPORT

Limit lubrication

Almost totally absent lubricating film

MIXED FRICTION - BODY - COUNTERBODY

Mixed lubrication

Partially-active lubricating film in some areas

FLUID FRICTION - BODY - COUNTERBODY

Hydrodynamic lubrication

Lubricant film present and active

Analysing the Stribeck curve, which explains the relationship between friction and sliding speed, the limit friction condition represents a situation of high wear damage coefficient. Why? The friction surfaces are almost always "uncovered", without lubricant protection. This is due to the lack of "dynamism"! Yes, precisely because the action of closing or opening the contact occurs quickly, there is no time for the lubricating film to "build" a homogeneous lubrication gap between the pin and the bush, as occurs for example in the case of rolling bearing lubrication. So what? What characteristics must the lubricating grease have? We explain it here.

Giuseppe Ruggeri tells us, "Mechanical wear, and therefore the loss of precision of the shaft-hole coupling, could lead - after a prolonged series of manoeuvres - to a non-symmetrical closure of the electrical contacts."

3) Lubricant solution in use: Teflon silicone grease

With the lubricant solution in use, being a Teflon-based silicone grease, the functionality tests conducted in the laboratories revealed mechanical wear due to friction in the contactors after a few million operations.

A desire to improve the quality of the product, however, led to the launch of a further internal test campaign, in search of a better-performing and longer-lasting lubricant solution.

Although this synthetic lubricant with a low coefficient of friction is a silicone grease thickened with Teflon, it is not the optimal solution due to its weak resistance to high surface pressures, typical conditions of metal-metal coupling.

Here we look at the strengths and weaknesses of a silicone grease.

4) Maconpaste HP: a new lubricant solution

The validation tests conducted with the new Maconpaste HP lubricating grease have highlighted an important result:

- No sign of significant wear of the pin-bushing coupling after double the millions of manoeuvres

- Perfect synchronisation of contact closure

At the end of the accelerated test in which the useful life of the device was simulated, the lubricating film was still present and effective on the points of friction. Wear at the end of the device's life was quantified as being reduced by 30%.

A lubricating fluid designed to protect against mechanical wear, in conditions of limit friction must be formulated taking into account some important precautions:

- Choose the right base oil viscosity - not too viscous so as to slow down the rapid actuation nor too fluid and lacking in lift

- Choose the right particle size for solid lubricants, which can create an effective physical barrier even when "cold"

- Go for a thickener with anti-wear additives incorporated - the particular structure of the thickener present in the Maconpaste HP formulation allows the same additives to work on the friction surfaces from the first movements

5) A custom-designed lubricating grease

In this article, we have demonstrated how - thanks to the experience of Lovato Electric - the use of a lubricant solution suitable for the operating conditions of a mechanical device can significantly contribute to product improvement.

Giuseppe Ruggeri also confirmed, "It is easy to find greases or lubricating oils on the market, even through a web search, but more difficult to find specific solutions for our application needs."

We agree completely! The “right” lubricant solution can make all the difference. In this article, born from the analysis of thousands of electromechanical parts not aligned with the desired function target, we look at how easy it is to destroy them with an unweighted lubricant choice.

With Maconpaste HP lubricating grease for other loads, it was possible to:

- Increase the useful operations of the contactor by 100%

- Detect a lubricating film even when the millions of operations are doubled

- Reduce lubricant costs by 30%

- Improve product quality by replacing the lubricant only, without changing any other details

Maconpaste HP lubricating grease

Reduces mechanical wear

High load capacity

Suitable for metal-metal couplings

Excellent emergency lubrication

Solid lubricants

Discover the main applications