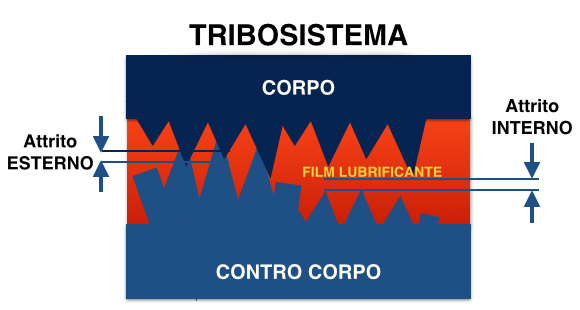

How to optimize the heat transfer between source and dissipator with a conductive paste with a high heat transfer coefficient.

Air is a poor conductor of heat, which means that its thermal conductivity is not enough to dissipate the energy that accumulates in the electromechanical devices. This is the reason why between the heat sink and the source device it is necessary to interpose a plastic film, capable of removing the air between the roughness of the surfaces and of conveying the thermal energy accumulated to the outside. A heat conducting paste is a practical and effective solution. But which are the best features that a good thermal paste needs to have? What chemical composition? How should you behave during prolonged exercise?

In this article we will outline the identikit of the best thermal pastes, analyzing 5 essential points which must not be ignored if you want to obtain an optimal heat transfer without loss of efficiency over time.

Thermalpaste 7001

Thermally conductive paste

Download the technical sheet.pdf

Check the performance of Thermalpaste 7001 thermal paste directly in your project!

Request a free sample

SEND INQUIRY

READ ALL