Find out how to friction kinematics with high friction lubricating fluid

Have you ever closed a kitchen drawer with a little too much enthusiasm? It closes quickly 95% of its route but just before closing, it slows right down until gently closing. And the cabinet doors? Same thing. Would you like to achieve the same effect in the mechanical device you are designing? Without having to devise complex kinematics of motion transmission, forced couplings and clutches but simply by interposing a high-friction lubricating grease between the sliding surfaces? Read on and you might just discover something new.

1) An introduction to "soft touch"

For several years in the automotive sectors, in the production of household appliances and furniture, there has been a tendency to design openings, closings and adjustments with the desire to transfer a “soft touch” sensation to the user. Meaning what? The user has the pleasure of "feeling" between the fingers a fluid, constant and slowed mechanism, free from jamming and with calibrated tolerances. Why?

Simply because you get a perception of greater quality and functionality.

High friction damping greases

Find out how to actively control the friction of your component at low cost

- Slowed closures and friction

- Smooth adjustments

- Precise and backlash-free couplings

- Recovery of wear between couplings

Gently accompanying the closing of a door, observing the slow descent of the car glove compartment or adjusting the fine movement of a camera on a tripod can, however, be very complicated from a design point of view and results in quite high construction costs. To obtain a soft close, it is necessary to have:

- A closing and opening guiding device

- A possible rearm mechanism

- A braking or friction control action

Although the realisation of the first two is obvious, if we think of the hinge of a piece of furniture in addition to the hinge described above in Point 1 along with the return spring in Point 2, it is necessary to provide "functional friction" only in the final part of the stroke, to guarantee a soft closure without bangs or flapping.

Recently, the use of "controlled" closing systems has also been introduced to meet needs related to safety in daily use:

- Decelerated hinges for mobile doors

- Linear shock absorbers for retractable doors

- Automotive interior handles

- Top-loading dishwasher opening

- Shock absorbers for toilet seats

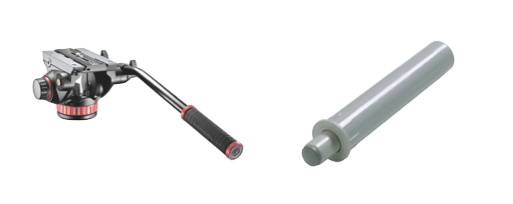

- Tripod adjustment for video shooting

- Mosquito net rollers

- Storage compartment drawer

- Armrests for cars

Is it possible to simplify the life of the designer through the use of an effective and easy-to-apply solution? Yes, with a damping lubricating grease.

2) What is a damping braking lubricating grease?

Simply speaking, we could define a damping braking grease as a compound with a high coefficient of friction. So, the opposite of a lubricating grease? Not really. The basic function of damping grease is to make the friction surfaces float, interposing a continuous, persistent and adhesive plastic and load-bearing film. However, without losing the lubricating and anti-wear functions typical of a traditional lubricating grease.

Applied and contained in the device, it keeps its properties unaltered for the entire life of the component, exerting a high-value "active" friction, capable of modulating the scrolling speed and creating the desired control effect.

Damping fluids can have an oily or greasy consistency. Their use is linked to the type of system in which they operate, being closed like a linear damper or semi-shielded such as the clutch of a camera-handling device.

Damping lubricating greases are more versatile as they do not need to be contained with gaskets or other sealing elements. They appear as sticky compounds, with a honey-like and stringy appearance as well as being very adhesive. They are formulated starting from high viscosity synthetic oils, inert thickeners to give the desired "consistency", and additives to promote stickiness and braking power.

3) How a damping lubricating grease works

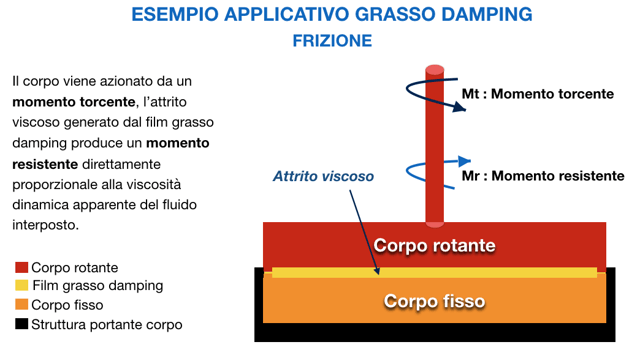

The operating principle of a damping grease is quite simple. The high length of the polymer chains of the oils used for its formulation generate an infinite number of attachment points to the surfaces in reciprocal sliding, with the result of producing a friction resistance of high value. Let's take, for example, a simple rotating clutch, as in the following image. The presence of a continuous film of grease produces a period of resistance of a value directly proportional to the viscous friction of the fluid at the operating temperature.

GREASE DAMPING APPLICATION EXAMPLE

CLUTCH

The body is driven by a twisting moment, with the viscous friction generated by the damping greasy film producing a resisting moment directly proportional to the apparent dynamic viscosity of the interposed fluid.

Rotating body

Damping grease film

Fixed body

Body supporting structure

Torque

Resistant moment

Viscous friction

Rotating body

Fixed body

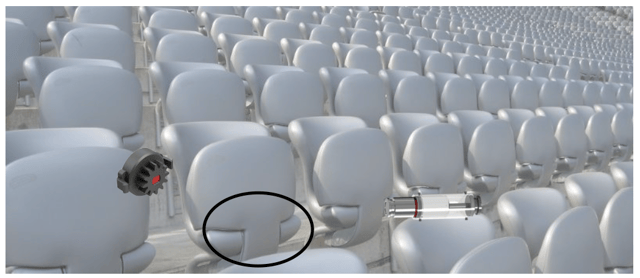

The system can be used to cushion the automatic recall of seats in a theatre or stadium. By releasing the clutch mechanism in one direction (descent) and activating it instead for reverse rotation (ascent), in antagonism with the return spring, the result will be a gentle rise of the seat.

4) Advantages of a damping brake grease

If we imagine a "slow" application context, as in the case of the clutch described above, where rotation speeds of 1 rpm are not exceeded, a damping lubricating fluid can in effect be assimilated to a traditional lubricant, with the following properties:

- Reduction of mechanical wear

- Corrosion protection

- Noise reduction

- Friction control

- Slack recovery

The most important advantage of a damping fluid is the possibility of defining the desired friction effect with a good approximation, in a given temperature range, tailor-made the solution based on the application requirements.

5) Dosage and application

The damping fluids are inert, not subject to hazard labels, do not polymerise and do not irreversibly change their state of aggregation in contact with plastics, rubbers or metals. They are generally compatible with most materials. Due to their high consistency, adhesiveness and stickiness, a semi-automatic hot dosing may be necessary in the most critical cases.

Do you want to evaluate the technical characteristics of a high friction coefficient damping grease? Do you want to check its application potential directly in your component? Request a sample!

High-friction damping greases

Find out how to actively control the friction of your component at low cost

Slowed-down closures and friction

Smooth adjustments

Precise and backlash-free couplings

Recovery of wear between couplings