A synthetic lubricating grease, even if more effective and valuable than a mineral, is not sufficient on its own to prevent the risk of breakages and even considerable damage to a mechanical component.

The doubts raised by users are recurrent: "I'm using a high-performance lubricating grease that costs four times the previous one, yet bearings are seizing frequently!" or "I replaced the chain lubrication oil and despite costing twice as much, the chain stretched by 10% and lasted half as long as before! Why?"

If you have any concerns that the lubricant in your mechanical component is not performing properly, first answer the following questions: Are you sure that the lubricant has been added into the component correctly? In the correct quantity and frequency? If you have used a centralised distribution system, are you sure that the grease has completely enveloped the friction area? How much oil did you add to the chain? Was the chain cleaned prior to being lubricated?

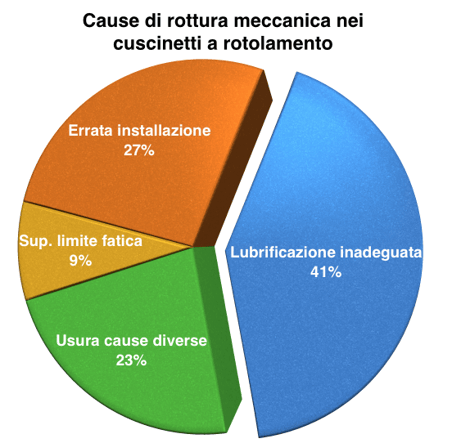

In numerous maintenance environments, the main causes of breakage are linked not only to the poor quality of the lubricating fluid but also to the incorrect supply on the friction points. Indeed, rolling bearing failures are caused by inadequate lubrication in 41% of cases! In this article, we will outline 5 good reasons to adopt an automatic lubricator to optimise the maintenance of your machines and reduce efficiency maintenance costs.

Do you want to lubricate your bearings, gears or chains with an automatic system? Do you want to ensure smooth and timely delivery using your lubricating grease?

(1) Correct lubricant supply

Each lubricating fluid has its own specific field of application. For this reason, a lubricating oil used for power reducers will not be as useful for a chain or fast bearing for example. Similarly, a soft grease with a NLGI 00 consistency would not be suitable for the lubrication and sealing of valves, given that it actually performs a sealing action.

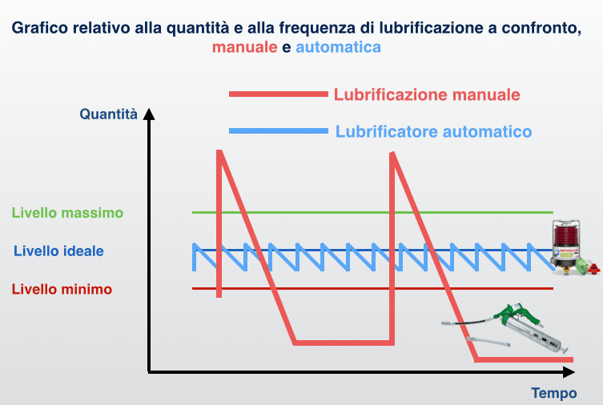

It is also important that the quantity of lubricant supplied to the friction areas is correct in terms of quantity and frequency. The risk of over-lubrication increases with manual operation compared to a mechanical dispenser. When an operator supplies lubricant with a specific frequency and dosage, the system becomes over-lubricated from the outset then reaches insufficient lubrication conditions long before the next scheduled maintenance.

All too often, operators fill the rolling bearing until full resulting in the grease spillage. As matter of fact, an excess of lubricant before and after the "pumping" of grease and a deficiency towards the end of the maintenance cycle would equally produce an increase in friction and operating temperatures due to the obstruction caused by the high quantity of grease in the first instance and prolonged contact between rolling elements and tracks in the second case.

Hence, the best lubricating grease in these examples would not result in proper operation. With the aid of an automatic lubricator, rather, the application requirements would be respected both in terms of quantity and frequency of lubrication.

Graph comparing the quantity and frequency of lubrication, manual and automatic

Manual lubrication

Automatic lubricator

Quantity

Maximum level

Ideal level

Minimum level

Time

(2) Reduction of faults

This would impede the rolling bearing from overheating, along with the risk of seizure or breakage. Indeed, by reducing the risk of operating the mechanical component in conditions of unsuitable lubrication, the risk of failures or breakages – typical upon a lack of lubrication – is also considerably reduced. In the case of rolling bearings, the lubrication is responsible for over 40% of malfunctions.

Causes of mechanical failure in rolling bearings

Incorrect installation

Fatigue limit exceeded

Other causes of wear

Inadequate lubrication

3) Reducing costs

Costs remain strongly influenced by two fundamental factors: the first, as we have just seen, is linked to the reduction of faulty components and the consequent reduction of purchases and relative costs, inventories and procurement times, while the second is linked to the assigned personnel. Reducing lubrication operations, being instead performed automatically by the lubricant system itself and only occasionally checked by the Company's system, staff can be assigned other tasks that cannot be effectuated by an electronic system.

(4) Increase in safety

Installing an automatic lubricator means resolving particular and difficult situations such as greasing wheel bearings of an overhead crane or a fan placed in an awkward and distant part of the installation, requiring the use of a forklift truck or asking operators to work in risky conditions. Yet, with an automatic lubricator, such operations can be made once per year instead of having to substitute or fill cartridges in the dispenser.

(5) Increase in the performance of the mechanical organ

Finally, good lubrication limits temperature increases with a consequent reduction in wear and tear.

As a general consequence of being correctly lubricated – in terms of time, quantity and type of lubricant used – it is possible to obtain consistent performance at the highest levels of the mechanical component, both from a productivity perspective due to the reduction of machine downtime and in terms of operating conditions.

In this article, we have talked about some of the advantages that can be obtained by fitting an automatic lubricator into an operating machine. However, it must be considered that those who produce greases and lubricating oils do not always produce automatic lubricators, whilst those who produce automatic lubricators do not always have the possibility to equip such equipment with lubricating fluids on the market. Today, this is no longer a problem!

Do you want to lubricate your bearings, gears or chains with an automatic system? Do you want to ensure smooth and timely delivery using your lubricating grease?